- Fire Pump System

-

- Containerized fire pump setFire Pump PackagesUL-Listed Fire Pump SetDiesel Fire Pump SetEJ Small Flow Fire Pump SetED Small fire pump setElectric Jockey Fire Pump SetFire Pump Set with Jockey PumpFire Pump SystemSplit Case Fire Pump SetMutistage EDJ Fire Pump SetEDJ Fire Pump SetDiesel Fire Pump Set with Jockey PumpFire Fighting Pump SystemElectric Diesel Jockey Fire Pump SetFire Fighting Pump Set with Jockey PumpSmall Capacity Electric Fire Pump SetDJ Fire Pump Set with Jockey PumpEJ Fire Pump SetED Fire Pump Set (Electric+Diesel pump)Diesel Engine Fire Pump SetEDJ End Suction Fire Pump SetDiesel Fire Jockey PumpSmall Fire Pump SetEDJ Fire Pump SystemFire Water Pump SetFire Pump AssemblyDJ Small Flow Fire Pump SetCummins Engine Fire Pump Set

- Mobile Pump Unit

-

- Split Case Series Mobile Pump TruckSelf Priming Series Mobile Pump TruckCentrifugal diesel driven dewatering pumps open frame trailerFlow-mixing Mobile Pump TruckFlow-mixing Mobile Pump TruckManure Pump TruckP12 modle mobile Pump truckP10 Modle Mobile Pump Truck1000m³Self Priming Series Mobile Pump TruckLarge Flow Non-Clogging Mobile Fire Pump TrailerTrailer Mounted Fire PumpFire Emergency Mobile Pump TruckDiesel Engine Emergency Mobile Trailer Pump

- Diesel Fire Pump

-

- UL Listed Diesel End Suction Fire PumpXBC-S Diesel Split Case Fire PumpXBC-IS Diesel End Suction Fire PumpXBC-D Diesel Multistage Fire PumpVertical Turbine Diesel Engine Fire PumpDiesel Engine Single-Stage Centrifugal PumpXBC-IS Diesel End Suction Fire Fighting PumpXBC-S Diesel Engine Split Case Fire PumpDiesel Engine End Suction Fire PumpXBC-IS Diesel End Suction Fire PumpsZWC Diesel Engine Self Priming Pump for IrrigationDiesel Engine End Suction Fire Fighting PumpXBC-S Heat Exchange Diesel End Suction Fire PumpXBC-XA Diesel Engine End Suction Fire PumpXBC-IS Diesel Engine Fire PumpDiesel Engine End Suction Fire PumpXBC-IS Diesel Engine End Suction Fire PumpXBC-ISO Diesel Fire Fighting PumpPortable Fire PumpFire Booster Pump

Email: zjbetter@119pump.com

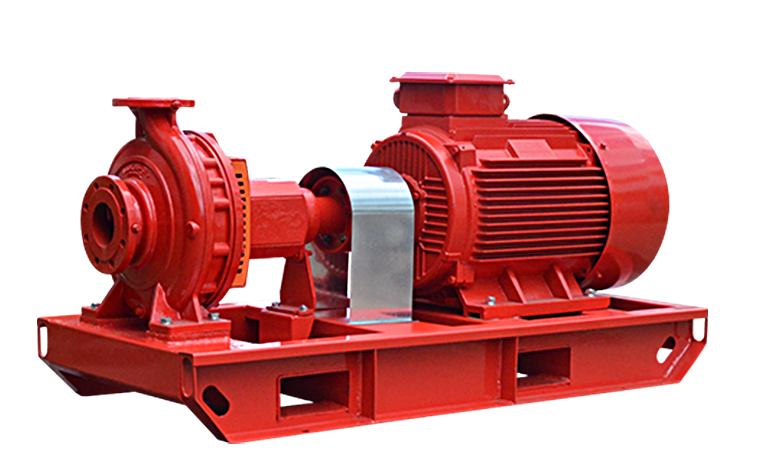

UL Listed ISO End Suction Centrifugal Pump

Flow: 1~300L/s

Head: 0.15~1.6MPa

Caliber: 25~500mm

Power: 0.75~160/6P kW

Speed: 960~2900r/min

Working Pressure: 1.6MPa

If you want to get more product information please contact us!

XBD-ISO Series Horizontal End Suction Centrifugal Pump

ISO series centrifugal pump is a single-stage single-suction centrifugal pump developed by China Better Technology Co., Ltd. with reference to international similar products using modern fluid mechanics to meet the international standard ISO9908 secondary energy efficiency standard.

This product combines the strengths of similar products in China and abroad and is designed with excellent hydraulic models, therefore, its excellent hydraulic performance and structural features ensure that the user can effectively reduce the operating cost of the pump in various applications.

The main technical parameters

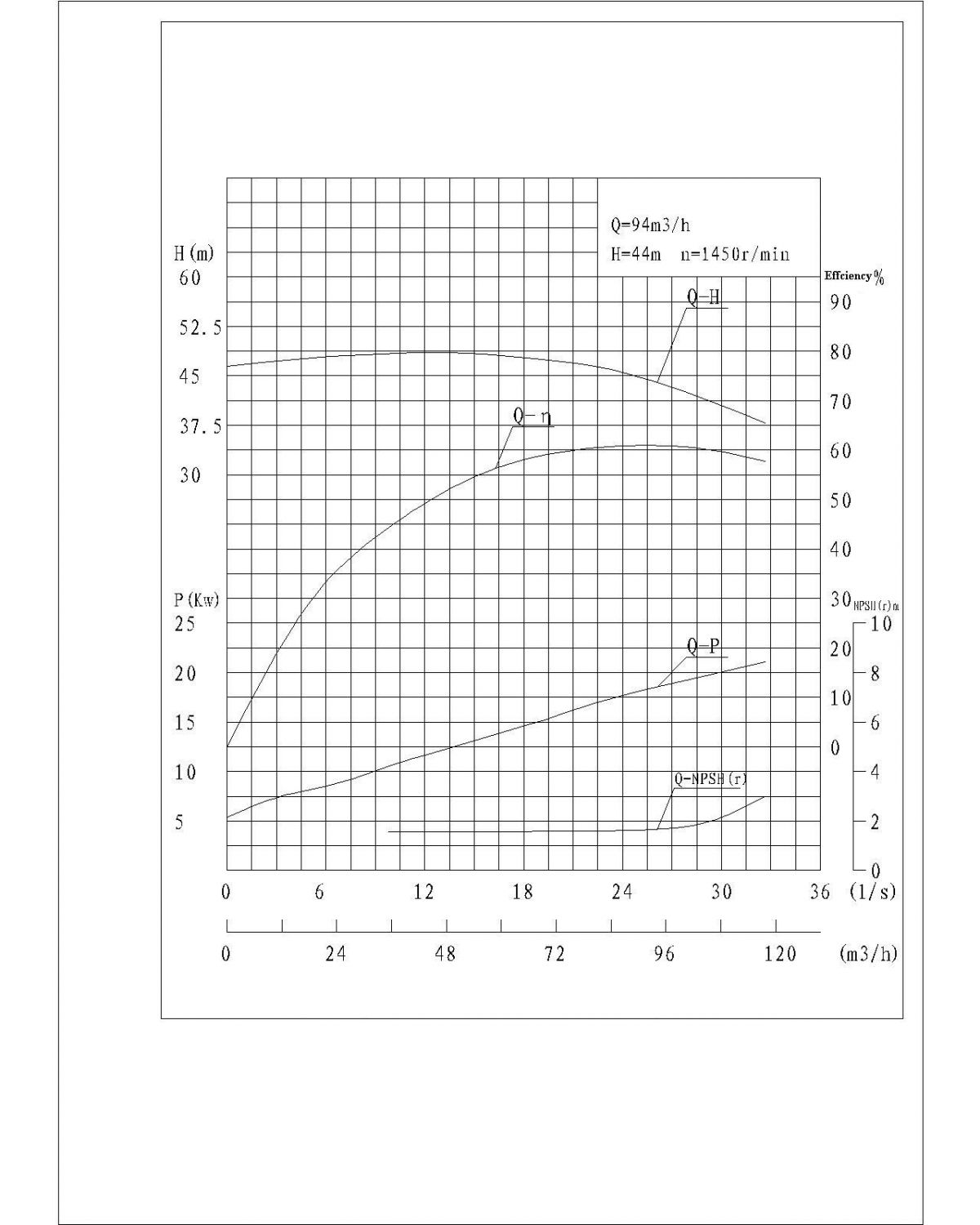

There are 36 kinds of specifications in the whole series, which can provide hundreds of performances with 6 different impeller diameters and 4 rotational speeds (including 60Hz) for selection.

| Pump diameter | suction 50 ~ 300mm, discharge 32 ~ 250mm |

| Flow rate | up to 1500m3/h |

| Head | up to 160m |

| Housing pressure | up to 1.6MPa at 20 ° C, Other materials such as ductile iron can sustain higher pressures. (housing pressure = inlet pressure + shut down head) |

| Medium temperature | -10°C~104°C, please specify when ordering more than 80°C. |

| Product Standard | Q/BD2104-2008 General Usage Centrifugal Pump |

| Note: When medium temperature is above 80°C or non-clear water medium is transported, please specify when inquiring or ordering. |

|

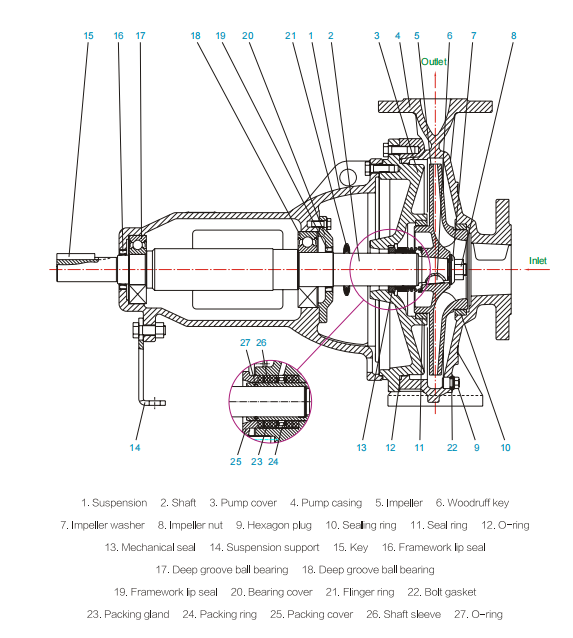

1. Pump Body: to lower the velocity of flow, making velocity energy into pressure energy.

2. Impeller: to play a leading role with its vane forcing liquid rotated and splashed around driven by centrifugal force.

3. Pressure Plug: to mount pressure gauge to monitor the normal operation of pump.

4. Air Release Valve: to release the air inside to ensure the normal start of pump.

5. Y/Y2 Series Motor: the driving part of pump, with a close coupled type.

6. Base: pump’s foundation, to ensure the stable of installation.

7. Water Deflector: to avoid water entering motor due to leakage at seal.

8. Pump Cover: elaborately designed of sharing the same end cover with motor, shortened axial dimensions and simple structure.

9. Mechanical Seal: made of stainless steel, tungsten carbide, fluorine rubber and etc, for outstanding sealing, durable service life and leak-tightness.

10. Pump Shaft: coaxial with motor and high concentricity to enable pump operating without noise and vibration.

11. Drain Plug: fully let out the liquid inside in case that pump needs servicing or will be left unused for a long time.

1. Application scope

Transporting clean water or weakly corrosive liquids without solid particles and fibers (wearing parts use stainless steel)

Construction

High-rise water supply, building fire protection, central air-conditioning water circulation

Industry

Circulation and cooling systems, boiler water supply and industrial water supply and drainage in industrial process systems.

Water supply

Water plant water supply, distribution and supercharging, artificial landscape water supply boosting, plantation irrigation, etc.

2. Using Instruction

Before start:

1. Turning the clutch by hand, there should be no jammed phenomenon at the turner position.

2. Opening the inlet valve and the vent valve, letting the water fill into the pump's chamber, then closing the vent valve.

3. Clicking the switch of motor, and confirming whether the turning is right or not.

Running:

1. Fully opening the inlet valves, and closing the valves of the outlet pipe.

2. Connecting the power, Opening the valves of the outlet pipe and adjusting the needed working point when the turning velocity is normal.

3. Watching whether there exist abnormities or not, if yes, should the pump be stopped and inspected before re-running.

Stop:

1. After turning off the outlet valves one by one, shutting off the power.

2. Shutting off the inlet valves.

3. If the ambient temperature is below 0, some warm keeping measures should be adopted.

Related products

InquiryPlease Feel free to give your inquiry in the form below. We will reply you in 8 hours.