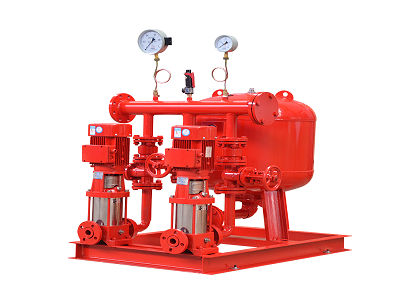

- Fire Pump System

-

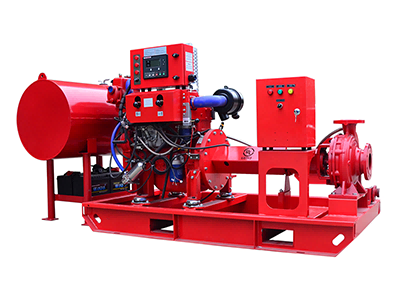

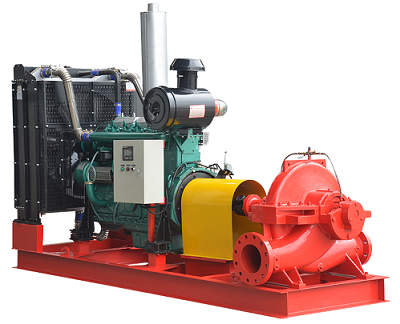

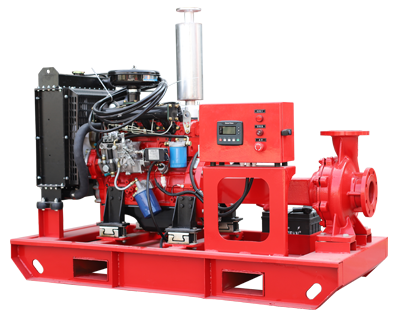

- UL-Listed Fire Pump SetEDJ End Suction Fire Pump SetEDJ Fire Pump SetEJ Small Flow Fire Pump SetFire Pump PackagesContainerized fire pump setDiesel Fire Pump SetED Small fire pump setElectric Jockey Fire Pump SetFire Pump Set with Jockey PumpFire Pump SystemSplit Case Fire Pump SetMutistage EDJ Fire Pump SetDiesel Fire Pump Set with Jockey PumpFire Fighting Pump SystemElectric Diesel Jockey Fire Pump SetFire Fighting Pump Set with Jockey PumpSmall Capacity Electric Fire Pump SetDJ Fire Pump Set with Jockey PumpEJ Fire Pump SetED Fire Pump Set (Electric+Diesel pump)Diesel Engine Fire Pump SetDiesel Fire Jockey PumpSmall Fire Pump SetEDJ Fire Pump SystemFire Water Pump SetFire Pump AssemblyDJ Small Flow Fire Pump SetCummins Engine Fire Pump Set

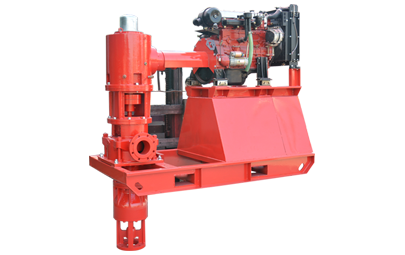

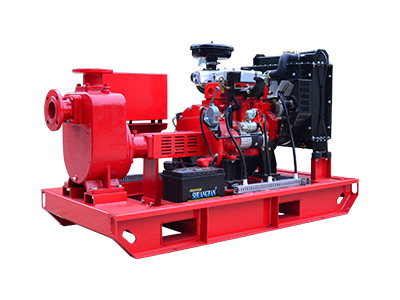

- Mobile Pump Unit

-

- Split Case Series Mobile Pump TruckSelf Priming Series Mobile Pump TruckCentrifugal diesel driven dewatering pumps open frame trailerFlow-mixing Mobile Pump TruckFlow-mixing Mobile Pump TruckManure Pump TruckP12 modle mobile Pump truckP10 Modle Mobile Pump Truck1000m³Self Priming Series Mobile Pump TruckLarge Flow Non-Clogging Mobile Fire Pump TrailerTrailer Mounted Fire PumpFire Emergency Mobile Pump TruckDiesel Engine Emergency Mobile Trailer Pump

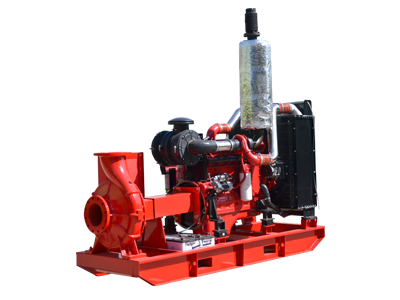

- Diesel Fire Pump

-

- UL Listed Diesel End Suction Fire PumpXBC-S Diesel Split Case Fire PumpXBC-IS Diesel End Suction Fire PumpXBC-D Diesel Multistage Fire PumpVertical Turbine Diesel Engine Fire PumpDiesel Engine Single-Stage Centrifugal PumpXBC-IS Diesel End Suction Fire Fighting PumpXBC-S Diesel Engine Split Case Fire PumpDiesel Engine End Suction Fire PumpXBC-IS Diesel End Suction Fire PumpsZWC Diesel Engine Self Priming Pump for IrrigationDiesel Engine End Suction Fire Fighting PumpXBC-S Heat Exchange Diesel End Suction Fire PumpXBC-XA Diesel Engine End Suction Fire PumpXBC-IS Diesel Engine Fire PumpDiesel Engine End Suction Fire PumpXBC-IS Diesel Engine End Suction Fire PumpXBC-ISO Diesel Fire Fighting PumpPortable Fire PumpFire Booster Pump

Email: zjbetter@119pump.com

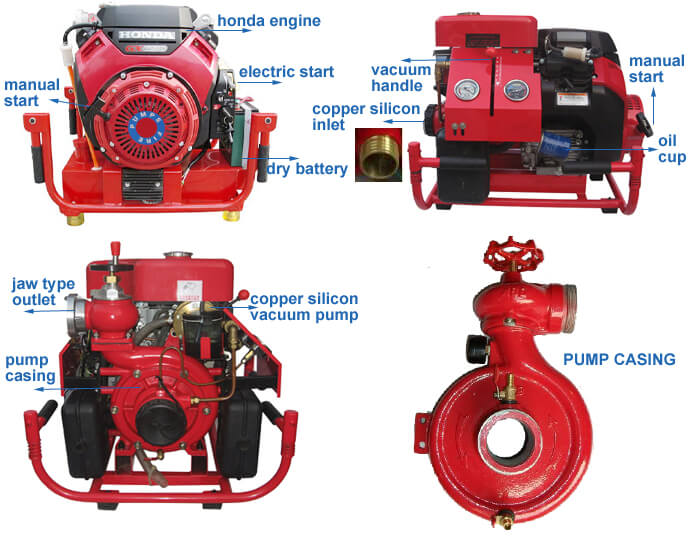

Portable Fire Pump

Power (Diesel,Petrol,Gasoline): 9 - 25 HP

Flow max.: 100gpm

Pressure: 0.7 mpa

Head: ≥ 60 m

Material: Cast iron

Model: JBQ

If you want to get more product information please contact us!

Portable Fire Pump Diesel Engine

The portable fire pump is well know for its simple structure, light weight, compact structure and high efficiency.For decades, it is hot saled in Southeast Aisa, Mideast, Africa and South America, it withstands the test of time.

As usual it inclues gasoline engine,centrifugal pump and scuttlebutt.

The power of regular type is 9 hp, 13 hp, 22 hp and 25 hp with max flow 500 gpm.

weight ≦ 100kg, vacuum sealing performance ≦ 2.6kPa, max. vacuum ≧ 85.0kPa, water diversion time ≦ 35.0s

Portable fire pump is mainly applied to the the professional fire brigade, industrial and mining enterprises,

and fire protection for suburbs/villages. It is most suitable for the place where the fire tender can't enter into.

As a famous portable fire pump manufacturer, zjbetter pump company is happy to supply you strong durable portable fire pump.

.jpg)

| 25HP | 13HP | |||||||||

| Total dimension | 650×610×650mm | Total dimension | 630×550×510mm | |||||||

| Device weight | 95kg | Device weight | 65kg | |||||||

| Max capacity | 475.5 gpm | Max capacity | 370 gpm | |||||||

| Rated capacity | 285 gpm | Rated capacity | 238 gpm | |||||||

| Pump head | 90m | Pump head | 65m | |||||||

| Outpressure | 0.7Mpa | Outpressure | 0.6Mpa | |||||||

| Inletsize | φ80mm | Inletsize | φ65mm | |||||||

| Outletsize | φ65mm | Outletsize | φ65mm | |||||||

| Dia.ofnozzle | φ19mm | Dia.ofnozzle | φ19mm | |||||||

| Typeofinlet | screwtype | Typeofinlet | screwtype | |||||||

| Maximumsuction | 7m | Maximumsuction | 7m | |||||||

| Pumpprimingtime | ≤20s | Pumpprimingtime | ≤20s | |||||||

| Startingway | Electricstart,manualstart | Startingway | Electricstart,manualstart | |||||||

| Modelofengine | 25HP,GX690 | Modelofengine | 13HP,GX390 | |||||||

| Impeller | 230mmAluminumalloy | Impeller | 170mmAluminumalloy | |||||||

| 9HP | 20HP | |||||||||

| Totaldimension | 550×500×400mm | Totaldimension | 650×710×650mm | |||||||

| Deviceweight | ≤40kg | Deviceweight | ≤80kg | |||||||

| Maxcapacity | 111 gpm | Maxcapacity | 211 gpm | |||||||

| Pumphead | 45m | Pumphead | 78m | |||||||

| Outpressure | 0.4Mpa | Outpressure | 0.63Mpa | |||||||

| Inletsize | φ65mm | Inletsize | φ80mm | |||||||

| Outletsize | φ65mm | Outletsize | φ65mm | |||||||

| Dia.ofnozzle | φ19mm | Dia.ofnozzle | φ19mm | |||||||

| Typeofinlet | screwtype | Typeofinlet | screwtype | |||||||

| Maximumsuction | 7m | Maximumsuction | 9m | |||||||

| Pumpprimingtime | ≤20s | Pumpprimingtime | ≤20s | |||||||

| Startingway | Electric,manualstart | Startingway | Electric,manualstart | |||||||

| Modelofengine | 9HP,177F | Modelofengine | 20HP,2V78F | |||||||

| Speed | 3600r/min | Speed | 3600r/min | |||||||

Pumps and accessories

The engine starting

Related products

-

- UL Listed Diesel End Suction Fire Pump

-

- XBC-S Diesel Split Case Fire Pump

-

- XBC-IS Diesel End Suction Fire Pump

-

.jpg)

- XBC-D Diesel Multistage Fire Pump

-

- Vertical Turbine Diesel Engine Fire Pump

-

.png)

- Diesel Engine Single-Stage Centrifugal Pump

-

.png)

- XBC-IS Diesel End Suction Fire Fighting Pump

-

.png)

- XBC-S Diesel Engine Split Case Fire Pump

-

.png)

- Diesel Engine End Suction Fire Pump

-

.png)

- XBC-IS Diesel End Suction Fire Pumps

-

- ZWC Diesel Engine Self Priming Pump for Irrigation

-

- Diesel Engine End Suction Fire Fighting Pump

-

.png)

- XBC-S Heat Exchange Diesel End Suction Fire Pump

-

.png)

- XBC-XA Diesel Engine End Suction Fire Pump

-

.png)

- XBC-IS Diesel Engine Fire Pump

-

.png)

- Diesel Engine End Suction Fire Pump

-

.png)

- XBC-IS Diesel Engine End Suction Fire Pump

-

.png)

- XBC-ISO Diesel Fire Fighting Pump

-

- Fire Booster Pump

InquiryPlease Feel free to give your inquiry in the form below. We will reply you in 8 hours.