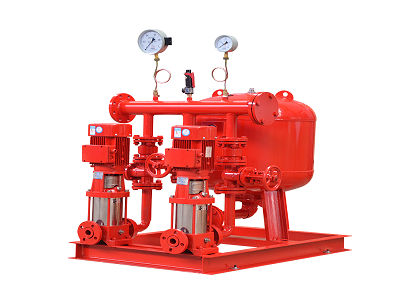

- Fire Pump System

-

- UL-Listed Fire Pump SetEDJ End Suction Fire Pump SetEDJ Fire Pump SetEJ Small Flow Fire Pump SetFire Pump PackagesContainerized fire pump setDiesel Fire Pump SetED Small fire pump setElectric Jockey Fire Pump SetFire Pump Set with Jockey PumpFire Pump SystemSplit Case Fire Pump SetMutistage EDJ Fire Pump SetDiesel Fire Pump Set with Jockey PumpFire Fighting Pump SystemElectric Diesel Jockey Fire Pump SetFire Fighting Pump Set with Jockey PumpSmall Capacity Electric Fire Pump SetDJ Fire Pump Set with Jockey PumpEJ Fire Pump SetED Fire Pump Set (Electric+Diesel pump)Diesel Engine Fire Pump SetDiesel Fire Jockey PumpSmall Fire Pump SetEDJ Fire Pump SystemFire Water Pump SetFire Pump AssemblyDJ Small Flow Fire Pump SetCummins Engine Fire Pump Set

- Mobile Pump Unit

-

- Split Case Series Mobile Pump TruckSelf Priming Series Mobile Pump TruckCentrifugal diesel driven dewatering pumps open frame trailerFlow-mixing Mobile Pump TruckFlow-mixing Mobile Pump TruckManure Pump TruckP12 modle mobile Pump truckP10 Modle Mobile Pump Truck1000m³Self Priming Series Mobile Pump TruckLarge Flow Non-Clogging Mobile Fire Pump TrailerTrailer Mounted Fire PumpFire Emergency Mobile Pump TruckDiesel Engine Emergency Mobile Trailer Pump

- Diesel Fire Pump

-

- UL Listed Diesel End Suction Fire PumpXBC-S Diesel Split Case Fire PumpXBC-IS Diesel End Suction Fire PumpXBC-D Diesel Multistage Fire PumpVertical Turbine Diesel Engine Fire PumpDiesel Engine Single-Stage Centrifugal PumpXBC-IS Diesel End Suction Fire Fighting PumpXBC-S Diesel Engine Split Case Fire PumpDiesel Engine End Suction Fire PumpXBC-IS Diesel End Suction Fire PumpsZWC Diesel Engine Self Priming Pump for IrrigationDiesel Engine End Suction Fire Fighting PumpXBC-S Heat Exchange Diesel End Suction Fire PumpXBC-XA Diesel Engine End Suction Fire PumpXBC-IS Diesel Engine Fire PumpDiesel Engine End Suction Fire PumpXBC-IS Diesel Engine End Suction Fire PumpXBC-ISO Diesel Fire Fighting PumpPortable Fire PumpFire Booster Pump

.png)

Email: zjbetter@119pump.com

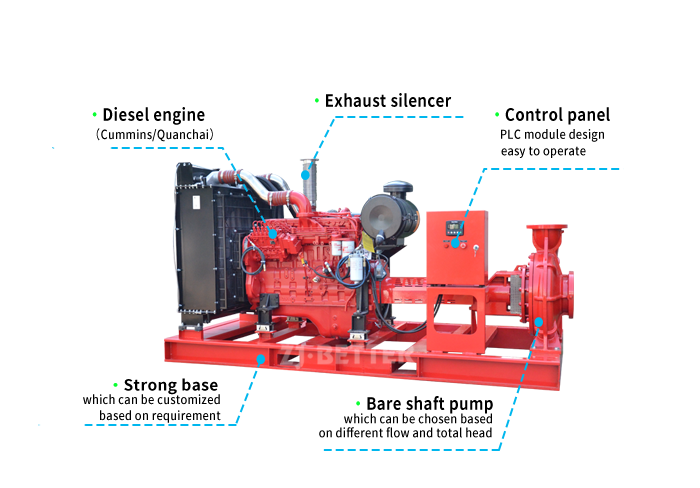

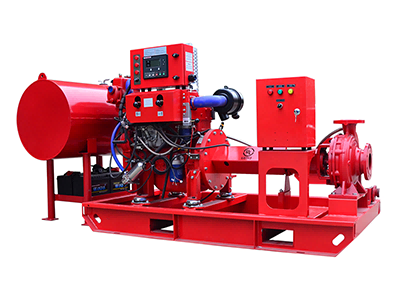

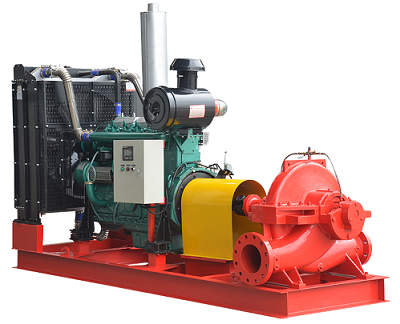

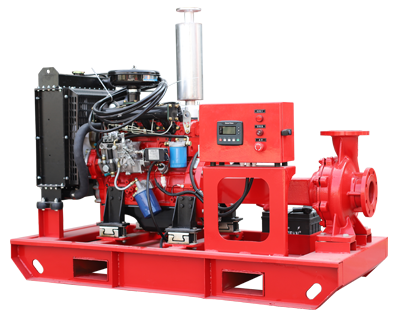

Diesel Engine Single-Stage Centrifugal Pump

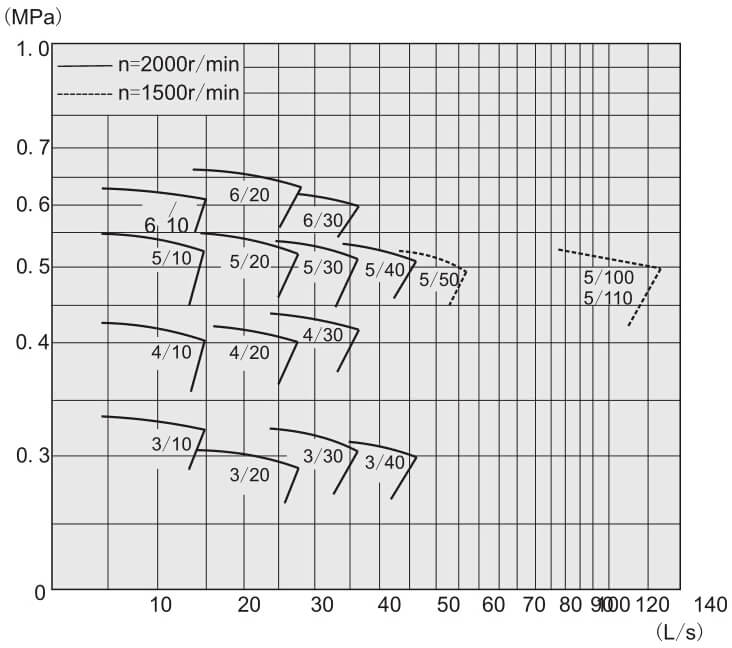

Flow: 80.0-2500 gpm

Head: 2-16 bar

Caliber: 50-250mm

Power: 3-220kW

Speed: 1500-2600r/min

Working Pressure: 1.6-2.5 MPa

If you want to get more product information please contact us!

Diesel Fire Pump XA Series Single-Stage Centrifugal Pump

XA series single-stage centrifugal pump is the earliest single-stage single-suction centrifugal pump product launched by Better (China) Technology Group Co., Ltd.

This product combines the advantages of similar products in China and abroad, and is designed with excellent hydraulic model.

Therefore, its excellent hydraulic performance and structural characteristics ensure that users can effectively reduce the operation cost of pumps in various applications.

Main Features

Meet high standards

XA single-stage single-suction centrifugal pump conforms to international standards: ISO9908, Technical Specification for Centrifugal Pumps,

Class III (Technical Specification for Centrifugal Pumps, Class III), mainly based on German DIN standard.

High-efficiency volute

The pump body is in the form of high-efficiency volute.

The flange connection size is in accordance with GB/T 17241.6-1998 (cast iron) and GB/T 9113.1-2000 (steel) PN1.6MPa,

and can be used with the following standard flanges. : BS 4504: 1989, ISO 7005.1: 1992, DIN 2533: 1976, ISO 7005.2: 1988.

Structural Design for Easy Installation

The rear open cover design can replace the rotor components without dismantling the pipeline.

Replaceable seal ring. The wear of the impeller ring can be achieved only by replacing the sealing ring,

so as to restore the best operating condition of the pump and achieve low-cost operation.

Ensure high reliability at high speed and heavy load operation

Cantilever ratio is small. The cantilever ratio of the rotor ranges from 0.66 to 1.1, with good rigidity and small deflection.

Its rigidity is much better than that of the same type of single-stage centrifugal pump (the cantilever ratio of IS pump is between 0.97 and 1.48).

Further Improve the Stability of Pump Operation

Hydraulic balance design and combination of impeller dynamic and static balance

Part standardization, high degree of Generalization

The 48 models of the whole series only need 5 suspensions, 6 pump shafts and 4 bearings.

Shafts, bearings, bushes, seals and impeller fasteners of the same specification can be interchanged,

which effectively improves the interchangeability of parts and reduces the inventory of spare parts.

Application scope

It is used to transport clean water and liquids with physical and chemical properties similar to water.

Water booster for waterworks or water supply company;

Circulation and cooling systems, boiler water supply and industrial water supply and drainage in industrial process systems.

Farmland irrigation and drainage, air conditioning systems, urban water supply and drainage, fire protection systems.

Related products

-

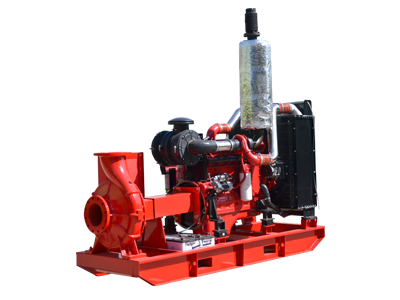

- UL Listed Diesel End Suction Fire Pump

-

- XBC-S Diesel Split Case Fire Pump

-

- XBC-IS Diesel End Suction Fire Pump

-

.jpg)

- XBC-D Diesel Multistage Fire Pump

-

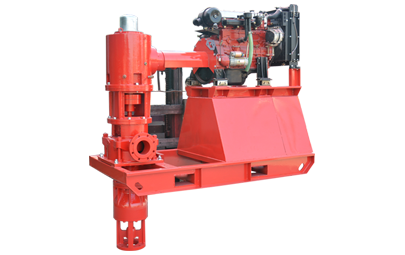

- Vertical Turbine Diesel Engine Fire Pump

-

.png)

- XBC-IS Diesel End Suction Fire Fighting Pump

-

.png)

- XBC-S Diesel Engine Split Case Fire Pump

-

.png)

- Diesel Engine End Suction Fire Pump

-

.png)

- XBC-IS Diesel End Suction Fire Pumps

-

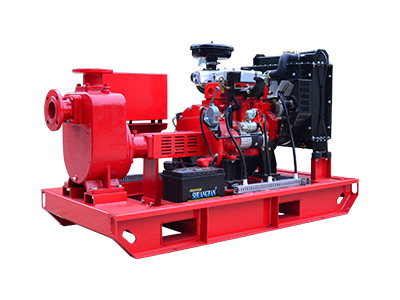

- ZWC Diesel Engine Self Priming Pump for Irrigation

-

- Diesel Engine End Suction Fire Fighting Pump

-

.png)

- XBC-S Heat Exchange Diesel End Suction Fire Pump

-

.png)

- XBC-XA Diesel Engine End Suction Fire Pump

-

.png)

- XBC-IS Diesel Engine Fire Pump

-

.png)

- Diesel Engine End Suction Fire Pump

-

.png)

- XBC-IS Diesel Engine End Suction Fire Pump

-

.png)

- XBC-ISO Diesel Fire Fighting Pump

-

- Portable Fire Pump

-

- Fire Booster Pump

InquiryPlease Feel free to give your inquiry in the form below. We will reply you in 8 hours.