- Fire Pump System

-

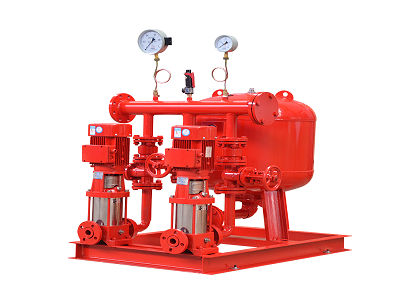

- UL-Listed Fire Pump SetEDJ End Suction Fire Pump SetEDJ Fire Pump SetEJ Small Flow Fire Pump SetFire Pump PackagesContainerized fire pump setDiesel Fire Pump SetED Small fire pump setElectric Jockey Fire Pump SetFire Pump Set with Jockey PumpFire Pump SystemSplit Case Fire Pump SetMutistage EDJ Fire Pump SetDiesel Fire Pump Set with Jockey PumpFire Fighting Pump SystemElectric Diesel Jockey Fire Pump SetFire Fighting Pump Set with Jockey PumpSmall Capacity Electric Fire Pump SetDJ Fire Pump Set with Jockey PumpEJ Fire Pump SetED Fire Pump Set (Electric+Diesel pump)Diesel Engine Fire Pump SetDiesel Fire Jockey PumpSmall Fire Pump SetEDJ Fire Pump SystemFire Water Pump SetFire Pump AssemblyDJ Small Flow Fire Pump SetCummins Engine Fire Pump Set

- Mobile Pump Unit

-

- Split Case Series Mobile Pump TruckSelf Priming Series Mobile Pump TruckCentrifugal diesel driven dewatering pumps open frame trailerFlow-mixing Mobile Pump TruckFlow-mixing Mobile Pump TruckManure Pump TruckP12 modle mobile Pump truckP10 Modle Mobile Pump Truck1000m³Self Priming Series Mobile Pump TruckLarge Flow Non-Clogging Mobile Fire Pump TrailerTrailer Mounted Fire PumpFire Emergency Mobile Pump TruckDiesel Engine Emergency Mobile Trailer Pump

- Diesel Fire Pump

-

- UL Listed Diesel End Suction Fire PumpXBC-S Diesel Split Case Fire PumpXBC-IS Diesel End Suction Fire PumpXBC-D Diesel Multistage Fire PumpVertical Turbine Diesel Engine Fire PumpDiesel Engine Single-Stage Centrifugal PumpXBC-IS Diesel End Suction Fire Fighting PumpXBC-S Diesel Engine Split Case Fire PumpDiesel Engine End Suction Fire PumpXBC-IS Diesel End Suction Fire PumpsZWC Diesel Engine Self Priming Pump for IrrigationDiesel Engine End Suction Fire Fighting PumpXBC-S Heat Exchange Diesel End Suction Fire PumpXBC-XA Diesel Engine End Suction Fire PumpXBC-IS Diesel Engine Fire PumpDiesel Engine End Suction Fire PumpXBC-IS Diesel Engine End Suction Fire PumpXBC-ISO Diesel Fire Fighting PumpPortable Fire PumpFire Booster Pump

Email: zjbetter@119pump.com

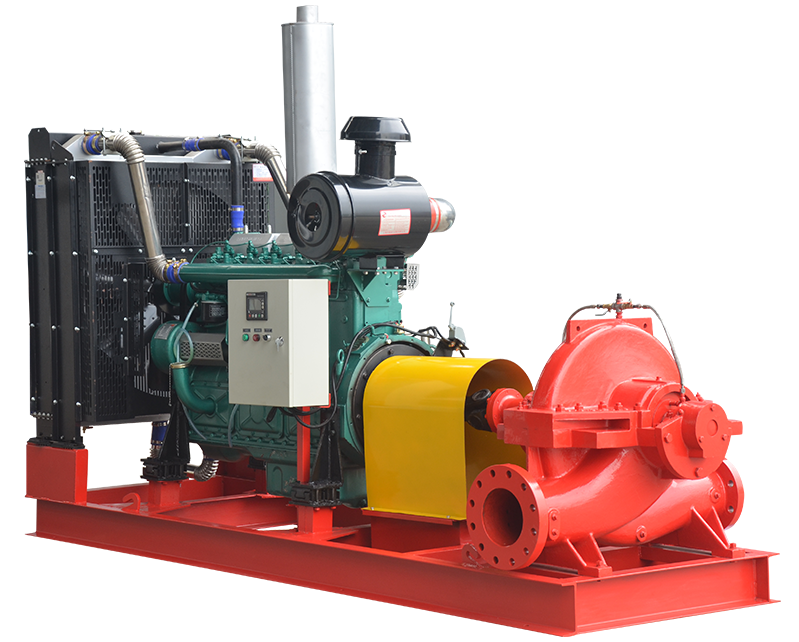

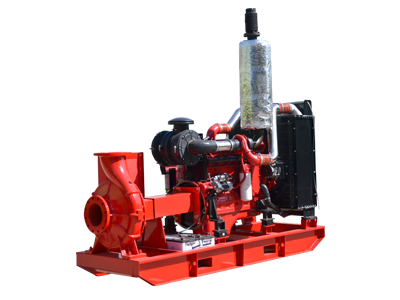

XBC-S Diesel Split Case Fire Pump

Flow: 1500-6000 gpm / 63-380l/s

Head: 5-12 bar / 72.5-174 psi

Caliber: 150-350mm

Power: 220-710kW

Speed: 1500r/min

Working Pressure: 1.6MPa

If you want to get more product information please contact us!

Product Introduction of XBD-S Split Case Fire Pump

XBD-S single stage double suction horizontal split case fire pumps are used to pump the clear water or other corrosive medium. S single stage double suction split case fire pumps are used to pump the clear water or other liquids with similar physical and chemical properties as clear water. The temperature of transported liquid shall not exceed 80. It is applicable for factory, mine, city water supply, power station, irrigation and drainage of farmland and various water conservancy projects.

Features

1. Split case design permits easy dis-assembly, that is, inspection is simplified, it is not necessary to disturb pump alignment and suction & discharge piping when parts replacement is necessary.

2. Double suction with advanced design of suction performance ensures high suction lift even with large capacity.

3. Pump operation with low noise and stability, in use ensure comfortable environment. Variable combination of materials permit wide application.

4. Drive shaft end of the pump optionally on the left or right. Shaft seal uncooled soft- packed stuffing box or uncooled single acting unbalanced mechanical seal, etc.

.jpg)

.jpg)

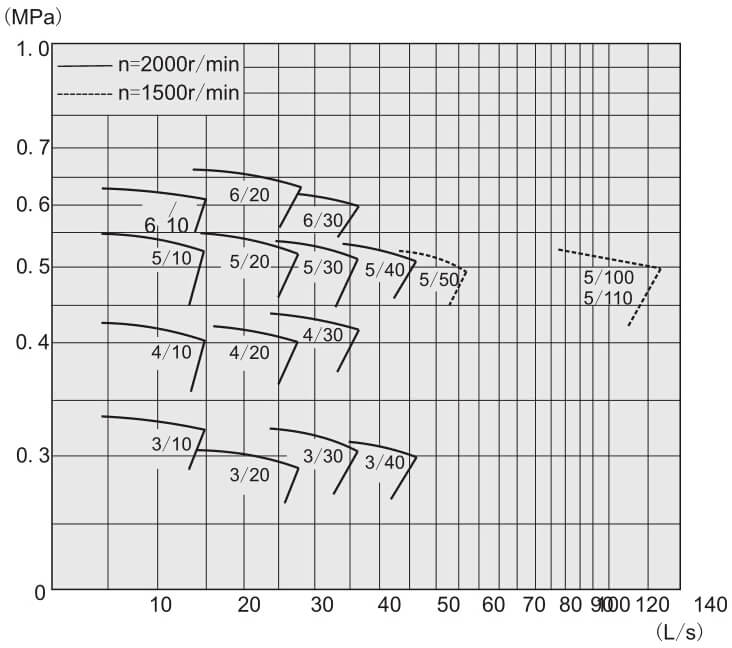

Parameters

| Model | Flow(m3/h) | Head(mpa) | Power(kw) | Speed (rpm) | Caliber (mm) |

| XBC2/5-IS | 2600 | 5 | 0.2 | 3 | 65/65 |

| XBC8/5-IS | 2000 | 5 | 0.8 | 7.5 | 50/50 |

| XBC6/10-IS | 2000 | 10 | 0.6 | 22 | 100/100 |

| XBC3/15-IS | 2600 | 15 | 0.3 | 11 | 80/80 |

| XBC10/15-TSWA | 1500 | 15 | 1 | 37 | 100/100 |

| XBC5/20-IS | 2000 | 20 | 0.5 | 22 | 125/125 |

| XBC8/20-DA | 1500 | 20 | 0.8 | 30 | 100/100 |

| XBC2.0/25(30)-D | 1500 | 25/30 | 0.2 | 11 | 125/125 |

| XBC9.0/25(30)-D | 1500 | 25/30 | 0.9 | 55 | 125/125 |

| XBC14.0/25(30)-D | 1500 | 25/30 | 1.4 | 75 | 125/125 |

| XBC8/35(40/45)-DA | 1500 | 35/40/45 | 0.8 | 75 | 150/150 |

| XBC21.0/35(40/45)-DA | 1500 | 35/40/45 | 2.1 | 160 | 150/150 |

| XBC2/50(55/60)-W | 1500 | 50/55/60 | 0.2 | 18.5 | 150/150 |

| XBC15/50(55/60)-D | 1500 | 50/55/60 | 1.5 | 132 | 150/150 |

| XBC5/80(85/90)-W | 1500 | 80/85/90 | 0.5 | 75 | 200/200 |

| XBC8/80(85/90)-W | 1500 | 80/85/90 | 0.8 | 90 | 200/200 |

| XBC1.6/80(85/90)-W | 1500 | 80/85/90 | 1.6 | 200 | 200/200 |

| XBC2/100(110/120)-W | 1500 | 100/110/120 | 0.2 | 45 | 250/250 |

| XBC6/100(110/120)-W | 1500 | 100/110/120 | 0.6 | 110 | 200/200 |

| XBC13/100(110/120)-W | 1500 | 100/110/120 | 1.3 | 220 | 250/250 |

| XBC5(6)/100(110/120)-S | 1500 | 100/110/120 | 0.5 | 132 | 250/150 |

| XBC6(7/8)/180(190/200)-S | 1500 | 180/190/200 | 0.6 | 315 | 250/150 |

| XBC5/250-S | 1500 | 250 | 0.5 | 220 | 250/200 |

| XBC7/300-S | 1500 | 300 | 0.7 | 315 | 300/250 |

| XBC10/300-S | 1500 | 300 | 1 | 630 | 350/250 |

| XBC7/350-S | 1500 | 350 | 0.7 | 355 | 300/250 |

| XBC12/350-S | 1500 | 350 | 1.2 | 710 | 350/250 |

| MORE SPECIFICATIONS PLEASE CONTACT US. | |||||

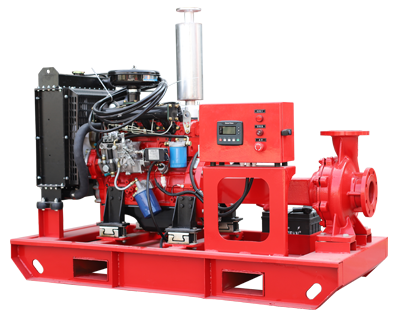

APPLICATIONS

Water works: Water intake/Water supply/Booster

Industrial use: Water intake/Water supply/Booster/Circulation/

Drainage/Chemical/Re-finery/Firefighting/Sea water desalination

Agricultural use: Irrigation and Drainage

APPLICATION RANGE

Capacity: Approx 75- 22000 m3 /hr.

Total head: Approx 10-220 m.

Liquid: Fresh water/ Industries/River water/Sea water/Brine/Paper stock Hydro-carbon etc.

.png)

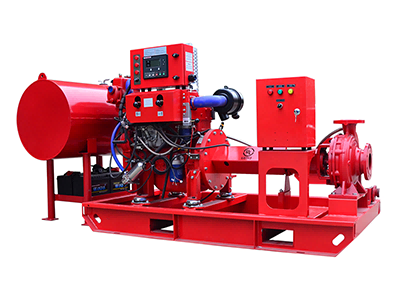

1-- Applicable for the XBC series diesel engine fire-fighting pump control made in this Co., and also for the diesel engine fire-fighting pump and diesel generator controls of users.

2-- It is applicable for water supply for fire service and emergency water supply.

3-- Suitable for the fire-fighting water supply and emergency water supply in storehouse, yard, airport, petroleum and chemical industry, power plant liquefied gas, textile, ship, and oil ship etc. occasions.

2. Using Instruction

1. The height of the machine room should be depended on the equipment’s height and the lifting apparatus, 3-5m ad the effective height in general.

2. To ensure a good ventilation inside of the machine room, the temperature there should not be over 40°C and enough venting temperature holes must be set.

3. When to mount both inlet and outlet pipes of the fire-fighting pump, do not let their weight loading on the pump so as to prevent it against damage and its performance of running from being affected.

4. It is not allowed to mount the control cabinet in the front of the diesel engine’s radiator, otherwise the electric components inside of the cabinet would be affected and not work normally.

Related products

-

- UL Listed Diesel End Suction Fire Pump

-

- XBC-IS Diesel End Suction Fire Pump

-

.jpg)

- XBC-D Diesel Multistage Fire Pump

-

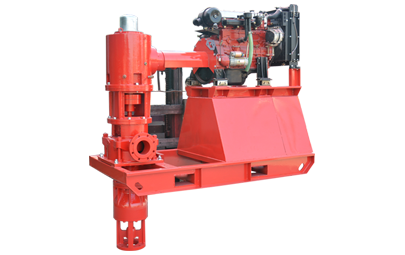

- Vertical Turbine Diesel Engine Fire Pump

-

.png)

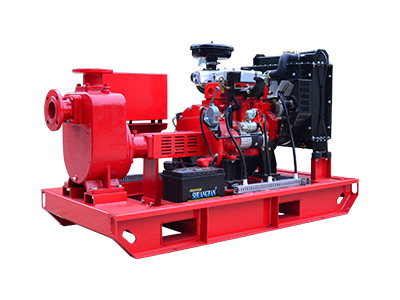

- Diesel Engine Single-Stage Centrifugal Pump

-

.png)

- XBC-IS Diesel End Suction Fire Fighting Pump

-

.png)

- XBC-S Diesel Engine Split Case Fire Pump

-

.png)

- Diesel Engine End Suction Fire Pump

-

.png)

- XBC-IS Diesel End Suction Fire Pumps

-

- ZWC Diesel Engine Self Priming Pump for Irrigation

-

- Diesel Engine End Suction Fire Fighting Pump

-

.png)

- XBC-S Heat Exchange Diesel End Suction Fire Pump

-

.png)

- XBC-XA Diesel Engine End Suction Fire Pump

-

.png)

- XBC-IS Diesel Engine Fire Pump

-

.png)

- Diesel Engine End Suction Fire Pump

-

.png)

- XBC-IS Diesel Engine End Suction Fire Pump

-

.png)

- XBC-ISO Diesel Fire Fighting Pump

-

- Portable Fire Pump

-

- Fire Booster Pump

InquiryPlease Feel free to give your inquiry in the form below. We will reply you in 8 hours.

.jpg)