- Fire Pump System

-

- Containerized fire pump setFire Pump PackagesUL-Listed Fire Pump SetDiesel Fire Pump SetEJ Small Flow Fire Pump SetED Small fire pump setElectric Jockey Fire Pump SetFire Pump Set with Jockey PumpFire Pump SystemSplit Case Fire Pump SetMutistage EDJ Fire Pump SetEDJ Fire Pump SetDiesel Fire Pump Set with Jockey PumpFire Fighting Pump SystemElectric Diesel Jockey Fire Pump SetFire Fighting Pump Set with Jockey PumpSmall Capacity Electric Fire Pump SetDJ Fire Pump Set with Jockey PumpEJ Fire Pump SetED Fire Pump Set (Electric+Diesel pump)Diesel Engine Fire Pump SetEDJ End Suction Fire Pump SetDiesel Fire Jockey PumpSmall Fire Pump SetEDJ Fire Pump SystemFire Water Pump SetFire Pump AssemblyDJ Small Flow Fire Pump SetCummins Engine Fire Pump Set

- Mobile Pump Unit

-

- Split Case Series Mobile Pump TruckSelf Priming Series Mobile Pump TruckCentrifugal diesel driven dewatering pumps open frame trailerFlow-mixing Mobile Pump TruckFlow-mixing Mobile Pump TruckManure Pump TruckP12 modle mobile Pump truckP10 Modle Mobile Pump Truck1000m³Self Priming Series Mobile Pump TruckLarge Flow Non-Clogging Mobile Fire Pump TrailerTrailer Mounted Fire PumpFire Emergency Mobile Pump TruckDiesel Engine Emergency Mobile Trailer Pump

- Diesel Fire Pump

-

- UL Listed Diesel End Suction Fire PumpXBC-S Diesel Split Case Fire PumpXBC-IS Diesel End Suction Fire PumpXBC-D Diesel Multistage Fire PumpVertical Turbine Diesel Engine Fire PumpDiesel Engine Single-Stage Centrifugal PumpXBC-IS Diesel End Suction Fire Fighting PumpXBC-S Diesel Engine Split Case Fire PumpDiesel Engine End Suction Fire PumpXBC-IS Diesel End Suction Fire PumpsZWC Diesel Engine Self Priming Pump for IrrigationDiesel Engine End Suction Fire Fighting PumpXBC-S Heat Exchange Diesel End Suction Fire PumpXBC-XA Diesel Engine End Suction Fire PumpXBC-IS Diesel Engine Fire PumpDiesel Engine End Suction Fire PumpXBC-IS Diesel Engine End Suction Fire PumpXBC-ISO Diesel Fire Fighting PumpPortable Fire PumpFire Booster Pump

.png)

Gallery

Email: zjbetter@119pump.com

CDL Jockey Pump

Flow: 1~300L/s

Head: 0.15~1.6MPa

Caliber: 25~500mm

Power: 0.75~160/6P kW

Speed: 960~3500r/min

Working Pressure: 1.6MPa

If you want to get more product information please contact us!

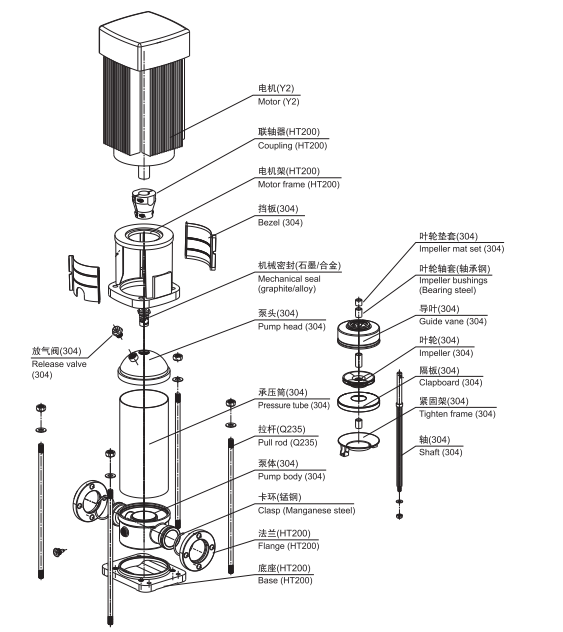

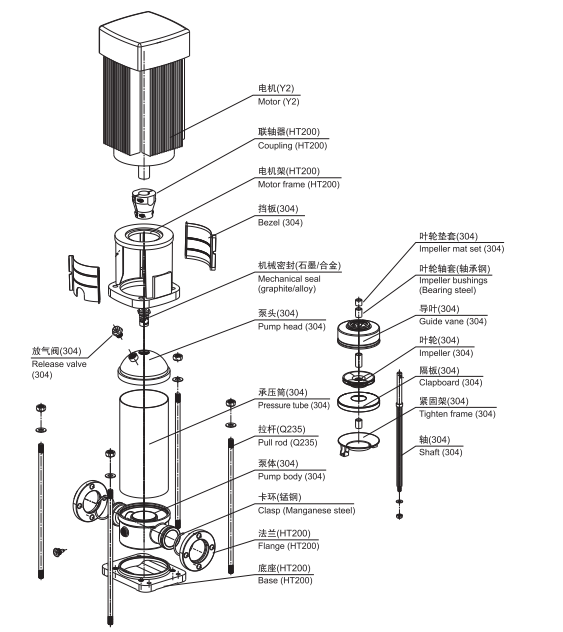

CDL VERTICAL MULTISTAGE CENTRIFUGAL PUMP

(Jockey Pump)

CDL/CDLF is a kind of vertical non-self priming multistage centrifugal pump, which is driven by a standard electric motor.

The motor output shaft directly connect with the pump shaft through a coupling.

The pressure-resistant cylinder and flow passage components are fixed between pump head and inlet &outlet section with stay bolts.

The inlet and outlet are located at the pump bottom at the same plane.

This kind of pump can be equipped with an intelligent protector to effectively prevent it from dry-running, out-of-phase and overload.

Motor

Full-enclosed air-blast two-pole standard motor

Protection class: IP55

Insulation class: F

Product Structure

1. Y/Y2 Series Motor: the driving part of pump, with a close- coupled type.

2. Pump Shaft: coaxial with motor and high concentricity to enable pump operating without noise and vibration.

3. Water Deflector: to avoid water entering motor due to leakage at seal.

4. Pump Cover: elaborately designed of sharing the same end cover with motor, shortened axial dimensions and simple structure.

5. Mechanical Seal: made of stainless steel, tungsten carbide, fluorine rubber and etc, for outstanding sealing, durable service life and leak-tightness.

6. Pressure Plug: to mount pressure gauge to monitor the normal operation of pump.

7. Pump Body: to lower the velocity of flow, making velocity energy into pressure energy

8. Drain Plug: fully let out the liquid inside in case that pump needs servicing or will be left unused for a long time.

9. Air Release Valve: to release the air inside to ensure the normal start of pump.

10. Impeller: to play a leading role with its vane forcing liquid rotated and splashed around driven by centrifugal force.

Application

CDL/CDL.F is a kind of multifunctional products. It can be used to convey various medium from tap water to industrial liquid at different temperature and with different flow rate and pressure. CDL type is applicable to conveying non-corrosive liquid, while CDLF is suitable for slightly corrosive liquid.

Water supply: Water filter and transport in Waterworks, boosting of main pipeline, boosting in high-rise buildings.

Industrial boosting: Process flow water system, cleaning system, high-pressure washing system, fire fighting system.

Industrial liquid conveying: Cooling and air-conditioning system, boiler water supply and condensing system machine-associated purpose acids and alkali

Water treatment: Ultra-filtration system, reverse osmosis system, distillation system, separator, swimming pool

Irrigation: Farmland irrigation, spray irrigation, drip ping irrigation.

Operation Conditions

Thin, clean, non-flammable and non-explosive liquid containing no solid granules and fibers.

Liquid temperature: Normal temperature type: -15 C-+70

Hot water type: +70C-+120C

Ambient temperature: up to +40 C

Altitude up to 1000m

1. Y/Y2 Series Motor: the driving part of pump, with a close- coupled type.

2. Pump Shaft: coaxial with motor and high concentricity to enable pump operating without noise and vibration.

3. Water Deflector: to avoid water entering motor due to leakage at seal.

4. Pump Cover: elaborately designed of sharing the same end cover with motor, shortened axial dimensions and simple structure.

5. Mechanical Seal: made of stainless steel, tungsten carbide, fluorine rubber and etc, for outstanding sealing, durable service life and leak-tightness.

6. Pressure Plug: to mount pressure gauge to monitor the normal operation of pump.

7. Pump Body: to lower the velocity of flow, making velocity energy into pressure energy

8. Drain Plug: fully let out the liquid inside in case that pump needs servicing or will be left unused for a long time.

9. Air Release Valve: to release the air inside to ensure the normal start of pump.

10. Impeller: to play a leading role with its vane forcing liquid rotated and splashed around driven by centrifugal force.

Application

CDL/CDL.F is a kind of multifunctional products. It can be used to convey various medium from tap water to industrial liquid at different temperature and with different flow rate and pressure. CDL type is applicable to conveying non-corrosive liquid, while CDLF is suitable for slightly corrosive liquid.

Water supply: Water filter and transport in Waterworks, boosting of main pipeline, boosting in high-rise buildings.

Industrial boosting: Process flow water system, cleaning system, high-pressure washing system, fire fighting system.

Industrial liquid conveying: Cooling and air-conditioning system, boiler water supply and condensing system machine-associated purpose acids and alkali

Water treatment: Ultra-filtration system, reverse osmosis system, distillation system, separator, swimming pool

Irrigation: Farmland irrigation, spray irrigation, drip ping irrigation.

Operation Conditions

Thin, clean, non-flammable and non-explosive liquid containing no solid granules and fibers.

Liquid temperature: Normal temperature type: -15 C-+70

Hot water type: +70C-+120C

Ambient temperature: up to +40 C

Altitude up to 1000m

Related products

InquiryPlease Feel free to give your inquiry in the form below. We will reply you in 8 hours.

.png)