In modern industrial parks, densely packed factories, concentrated equipment, and high requirements for continuous production mean that fires spread rapidly, consume large amounts of water, and are extremely difficult to extinguish. The success of initial fire suppression depends directly on whether the fire protection system has sufficient, stable, and continuous water supply capacity. Compared to fire protection equipment reliant on municipal power, high-flow-rate diesel fire pump systems, with their independent power, strong delivery capacity, and high reliability, have become indispensable core equipment in industrial park fire protection projects. This article will systematically analyze the key role of high-flow-rate diesel fire pump systems in industrial park fire protection from multiple perspectives, including product structure, performance advantages, operational stability, and application value.

1. High-Flow Output Capacity Meets the High-Intensity Fire Protection Needs of Industrial Parks Industrial park fires typically involve large-area factories, warehouses, and multi-story buildings. The instantaneous water supply demand during fire suppression is far higher than that of ordinary civil buildings. High-flow-rate diesel fire pump systems are designed from the outset with high flow rate and continuous water supply as their core objective. By optimizing the hydraulic model, increasing the impeller diameter, and expanding the pump body flow channel size, the water delivery capacity per unit time is significantly improved. Even with multiple fire hoses operating simultaneously and indoor and outdoor fire hydrants working in parallel, the system maintains stable output, effectively preventing problems such as shortened spray distance or reduced fire extinguishing efficiency due to insufficient flow. For high-risk areas such as chemical plants, heavy manufacturing bases, and logistics and warehousing parks, high flow output capacity is a fundamental guarantee for ensuring the effectiveness of the fire protection system.

2. Diesel-driven system ensures continuous operation in power outage environments. Industrial parks often experience partial or complete power outages during fires. If fire pumps rely on external power, they are highly susceptible to failure at critical moments. Diesel fire pump systems use internal combustion engines as their power source, operating completely independently of the power grid. Even in the event of a power outage or damage to the power distribution system, they can still start quickly and continue supplying water. Diesel engines are characterized by fast start-up response and strong load adaptability, and can operate stably in high-temperature, humid, or complex environments. This advantage is irreplaceable for ensuring fire safety in industrial parks under extreme conditions and is the preferred power source in many fire protection codes and engineering solutions.

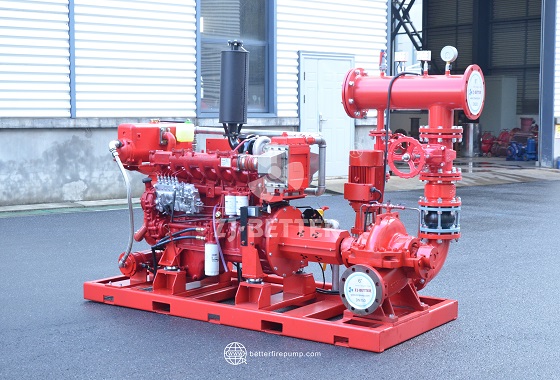

3. Standardized System Design Enhances Overall Operational Reliability: High-flow diesel fire pumps are typically delivered as complete systems, encompassing multiple key components such as the pump body, diesel engine, control system, cooling system, fuel system, and base structure. This standardized design avoids compatibility issues arising from on-site assembly, ensuring that each subsystem is matched and tested before leaving the factory, resulting in more stable and reliable overall operation. The unified structural layout not only facilitates transportation and installation but also aids in subsequent maintenance and management. In scenarios like industrial parks where equipment is concentrated and operating cycles are long, overall system reliability is far more important than the performance of individual components, and the standardized diesel fire pump system perfectly meets this requirement.

4. Stable and Durable Structure Adapts to Long-Term Operation in Industrial Environments: Industrial parks present complex environments with various adverse factors such as dust, oil, high temperatures, and humidity, placing higher demands on the durability of fire-fighting equipment. High-flow diesel fire pump systems typically employ high-strength cast pump bodies, wear-resistant shaft seals, and thickened base structures. Key components undergo anti-corrosion, anti-rust, and vibration damping treatments, enabling long-term stable operation under harsh conditions. Meanwhile, the system's design fully considers issues such as thermal expansion and contraction, vibration, and impact. Through reasonable support structures and connection methods, it reduces the failure rate during long-term operation, providing a durable and reliable fire water supply guarantee for industrial parks.

5. Automatic Control Functions Shorten Fire Response Time The speed of response in the initial stages of a fire directly affects the extent of damage. Modern high-flow-rate diesel fire pump systems are generally equipped with automatic start-up and monitoring functions. When the pipeline pressure drops abnormally or a fire signal is received, the system can start up and enter a stable water supply state in a very short time, reducing delays caused by manual intervention. Simultaneously, the control system can monitor operating parameters in real time, such as speed, oil pressure, water pressure, and temperature, ensuring that the equipment always operates under safe conditions. For industrial parks, this automation capability significantly improves overall fire response efficiency and is a key means to achieve "rapid water supply and rapid control."

6. Strong Adaptability Meets Diverse Fire Pipeline Layouts The internal pipeline layout of industrial parks is complex, and different areas have different requirements for head, flow rate, and pressure. High-flow diesel fire pump systems possess excellent adaptability to various operating conditions. Parameters can be configured according to actual project needs to meet diverse requirements, including long-distance water delivery, high-lift water supply, and multi-point parallel water supply. Simultaneously, the system can be flexibly connected to various fire protection facilities such as indoor fire hydrants, outdoor fire hydrants, and sprinkler systems, achieving unified water supply management. This strong adaptability allows for wide application in fire protection projects in industrial parks of different sizes and types.

7. Continuous Operation Capability Ensures Long-Term Firefighting Needs

In large industrial fires, firefighting often requires several hours or even longer, placing extremely high demands on the continuous operation capability of fire pumps. High-flow diesel fire pump systems are designed with long-term high-load operation requirements in mind. Through efficient cooling systems, stable lubrication structures, and reasonable fuel supply methods, the system ensures that the equipment is not prone to overheating or performance degradation during long-term operation. Stable continuous operation capability ensures that the fire protection system maintains a sufficient water supply during prolonged firefighting operations, providing a solid guarantee for controlling the spread of fire.

8. Installation Flexibility Suitable for Diverse Site Conditions in Industrial Parks

Industrial parks are often limited by space, terrain, or existing facilities during construction or renovation. High-flow diesel fire pump systems typically employ an integrated base structure, allowing for flexible placement in pump rooms, outdoor platforms, or dedicated equipment areas. Some models can also be customized to adapt to different installation conditions. The modular structure makes on-site installation more convenient, reducing construction time and project costs. This installation flexibility greatly improves the feasibility and economy of industrial park fire protection system construction.

9. Convenient Maintenance Reduces Long-Term Operating Costs

Although fire-fighting equipment is not frequently used under normal circumstances, its reliability must be ensured when needed. High-flow diesel fire pump systems are designed with ease of maintenance in mind, with a rational layout of key components, simplifying daily inspection, maintenance, and parts replacement. The clear structure and standardized components enable maintenance personnel to quickly complete routine maintenance work, reducing long-term management costs. For large-scale industrial parks, ease of maintenance not only affects equipment lifespan but also directly impacts the sustainable operation of the overall fire protection system.

10. Compliance with Industrial Fire Protection Standards Enhances Overall Safety Level Industrial park fire protection systems must comply with relevant fire protection standards and engineering specifications. High-flow-rate diesel fire pump systems are designed with industrial fire protection requirements in mind in terms of design parameters, material selection, and performance indicators. Their stable water supply capacity, reliable start-up performance, and comprehensive control functions make them a crucial component in fire protection acceptance and engineering applications. By configuring high-flow-rate diesel fire pump systems, industrial parks can significantly improve their overall fire safety level, providing more reliable safety guarantees for production and business activities.

In summary, high-flow-rate diesel fire pump systems play an irreplaceable and critical role in industrial park fire protection. Their powerful water supply capacity, independent power advantage, stable and reliable structural design, and good adaptability enable them to cope with the high-intensity and long-term fire suppression needs of industrial fires. As industrial parks continue to expand and fire protection requirements become increasingly stringent, high-flow-rate diesel fire pump systems will continue to be core equipment in industrial fire protection engineering, providing solid support for industrial safety.