Against the backdrop of accelerating urbanization and increasing density of industrial facilities and large buildings, fire risks exhibit characteristics such as sudden onset, rapid spread, and short rescue windows. Especially in outdoor areas, remote locations, or environments with unstable power supply, the reliability of the fire protection system directly determines whether initial fires can be effectively controlled. Diesel fire pump units, with their advantages of independence from mains power, rapid start-up, and stable water supply, have become indispensable core equipment in outdoor fire protection systems. This article will comprehensively discuss the continuous water supply capabilities of outdoor-specific diesel fire pump units in the event of a sudden fire, from multiple perspectives including structural design, power system, operating performance, and applicable scenarios.

1. Diesel-driven system ensures independent operation in power-outage environments

Outdoor fire protection scenarios often face difficulties in power access or power outages during fires. One of the core advantages of diesel fire pump units is their complete independence from external power systems. The unit uses a diesel engine as the power source, directly driving the fire pump through mechanical transmission. Even in the event of a complete mains power failure, it can still stably supply fire-fighting water. This independent operating capability is particularly crucial in chemical parks, mining areas, ports and docks, and outdoor storage bases. Diesel engines have a mature and reliable technological foundation, are highly adaptable to fuel types, and can maintain stable operation in complex outdoor environments such as high temperatures, low temperatures, or high humidity, fundamentally guaranteeing the availability of the fire protection system in emergencies.

2. Rapid start-up performance gains valuable time in the initial stages of a fire

The success or failure of dealing with a sudden fire largely depends on whether the fire protection system can be put into operation in the shortest possible time. Outdoor-specific diesel fire pump units place great emphasis on start-up performance in their design. By optimizing engine matching, fuel supply systems, and start-up control methods, they achieve rapid response capabilities. The unit can use electric start or manual emergency start methods, quickly completing engine ignition and pump operation after receiving a start signal, establishing stable pressure and flow in a short time. For outdoor fire scenarios where the fire spreads rapidly, this rapid start-up capability can provide effective hydraulic suppression in the initial stages, gaining crucial time for subsequent firefighting operations. 3. Continuous and Stable Water Supply Capacity to Meet Long-Term Firefighting Needs

Unlike short-term emergency equipment, diesel fire pump units are designed from the outset to meet the practical needs of long-term continuous operation. The unit achieves this by rationally matching the diesel engine power with the fire pump performance parameters, enabling it to stably output flow and head for extended periods under rated operating conditions, avoiding performance degradation due to overload. The cooling system, lubrication system, and fuel system are all reinforced for continuous operation, ensuring the engine remains reliable even under high load conditions. For large outdoor fires or complex scenarios with recurring fires, continuous water supply capacity is a core factor in ensuring effective firefighting, and diesel fire pump units are specifically designed for such needs.

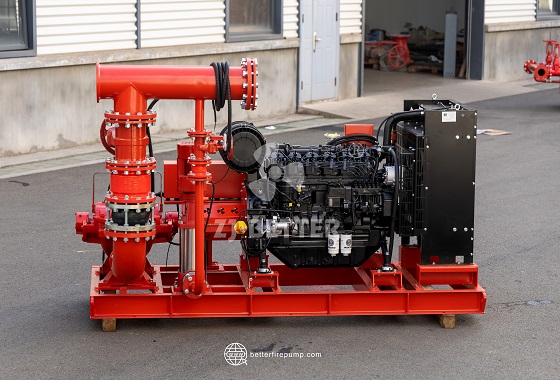

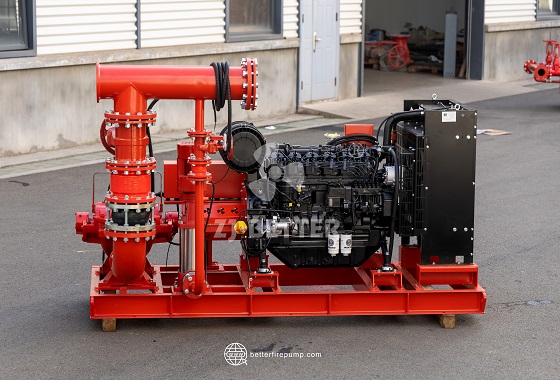

4. Robust Structural Design to Adapt to Complex Outdoor Environments

Outdoor environments often present unfavorable factors such as large temperature differences, high dust levels, high humidity, and frequent vibrations, placing higher demands on the structural strength and protection capabilities of firefighting equipment. Outdoor-specific diesel fire pump units typically employ an integral steel base structure, possessing excellent shock resistance and load-bearing capacity, allowing for stable operation on uneven ground or under temporary installation conditions. Key components are treated with anti-corrosion and anti-rust coatings, effectively resisting erosion from rain, salt spray, and chemical gases. Through structural reinforcement and rational layout, the unit maintains good mechanical stability and operational safety even with long-term outdoor placement or frequent starts and stops.

5. High Head and Large Flow Design to Address Diverse Fire Scenarios

The demand for fire water supply varies significantly in different outdoor locations. Some require long-distance water delivery, others require water supply to high elevations, and still others require a large volume of water in a short time. Diesel fire pump units can be configured with parameters according to actual application needs, balancing both high head and large flow output capabilities. By optimizing the pump body hydraulic model and impeller structure, stable pressure output is achieved while maintaining efficiency. This flexible performance adaptability allows the unit to be widely used in large factory areas, logistics parks, oil depots, docks, and outdoor areas with significant elevation differences, truly achieving "one machine for multiple uses."

6. Comprehensive Cooling and Heat Dissipation System to Ensure Operation in High-Temperature Environments

Outdoor fires are often accompanied by high-temperature environments, and the firefighting equipment itself generates a large amount of heat due to prolonged high-load operation. Diesel fire pump units are designed with a strong emphasis on the reliability of their cooling and heat dissipation systems. They typically employ a combination of high-efficiency radiators and forced air or water cooling to ensure the engine and pump body remain within a reasonable operating temperature range. Even in high summer temperatures or elevated temperatures at a fire scene, the unit can maintain stable operation, avoiding the risk of shutdown due to overheating and providing a solid guarantee for continuous firefighting.

7. Intelligent Control System Enhances Safety and Convenience

With the increasing intelligence of fire fighting equipment, outdoor-specific diesel fire pump units are gradually incorporating more comprehensive control and monitoring functions. Through an integrated control cabinet, users can achieve centralized management of startup, operating status, parameter monitoring, and fault alarms. The system can monitor key parameters such as rotational speed, oil pressure, and water temperature in real time, issuing warnings immediately if any abnormalities occur, preventing the equipment from continuing to operate in an unsafe state. This intelligent control not only improves the safety of the equipment but also lowers the technical requirements for operators, allowing the unit to be quickly and accurately deployed in emergency situations.

8. Ease of Maintenance Reduces Long-Term Operating Costs

Although fire fighting equipment is not frequently used, it must be reliable when needed, making routine maintenance particularly important. Diesel fire pump units are designed with maintenance convenience in mind. Key maintenance areas such as filters, oil line connections, cooling systems, and electrical connections are easily accessible for inspection and replacement. The modular design approach makes component replacement more efficient, effectively shortening maintenance time. For fire fighting systems deployed outdoors for extended periods, the controllability of maintenance costs directly impacts overall operating efficiency, and diesel fire pump units demonstrate a significant advantage in this respect.

9. Wide Applicability Meets the Outdoor Fire Fighting Needs of Multiple Industries

Outdoor-specific diesel fire pump units are not limited to a single industry but have a wide range of applications. In the industrial sector, they can be used in key fire protection areas such as chemical plants, energy facilities, and manufacturing parks; in the infrastructure sector, they can be applied to tunnels, bridge construction sites, and transportation hubs; and in the public safety sector, they can also be deployed as emergency fire fighting equipment in urban outskirts or temporary event venues. Their flexible configuration and reliable operating characteristics allow them to adapt to the needs of outdoor fire fighting systems of different scales and risk levels.

10. Core Equipment that Aligns with the Overall Design Concept of Fire Protection Systems

Modern fire protection systems emphasize multi-layered protection and system coordination, and diesel fire pump units are an indispensable core component. As a power guarantee device for a stable water source, it can efficiently cooperate with pipe networks, valves, sprinkler systems, and other fire protection facilities to quickly establish a complete water supply system in the event of a fire. Through rational selection and system integration, diesel fire pump units not only improve the overall reliability of outdoor fire protection systems but also enhance the comprehensive defense capabilities against sudden fires.

In summary, outdoor-specific diesel fire pump units demonstrate irreplaceable value in various sudden fire scenarios due to their independent operation capabilities, rapid start-up performance, continuous and stable water supply, and high adaptability to complex environments. Their robust structural design, flexible performance configuration, and intelligent control methods make them crucial equipment for ensuring the safety of life and property in outdoor fire protection systems. For fire protection projects that demand high reliability and long-term stable operation, diesel fire pump units are undoubtedly the ideal choice for responding to sudden fires and ensuring continuous water supply.