In modern fire protection system construction, the reliability of fire water supply equipment directly determines the success or failure of firefighting operations. Especially in industrial plants, energy facilities, municipal infrastructure, and remote areas, conventional electric fire protection systems often struggle to operate reliably under power outages, insufficient load, or harsh environmental conditions. Open-type diesel fire pump units, with their independent power source, straightforward structure, and stable operation, have become indispensable equipment in emergency and industrial fire protection. This article will systematically analyze the core value of open-type diesel fire pump units from multiple dimensions, including structural design, power system, operating performance, control methods, and application adaptability.

1. Open-Type Structural Design for Intuitive Operation and High Maintainability

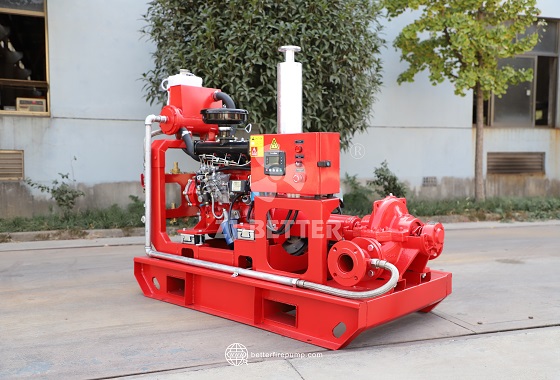

Open-type diesel fire pump units adopt an overall structural design without an enclosed casing. The engine, pump body, piping, control components, and other key units are all visibly arranged on a skid-mounted base. This structural form offers significant advantages in fire protection applications. First, the equipment status is clear at a glance, facilitating daily inspections and operation monitoring. Any leaks, looseness, or abnormal vibrations can be quickly detected and addressed. Second, the open layout provides ample operating space for inspection and maintenance. Routine maintenance, replacement of wear parts, or system debugging can be completed without disassembling the outer casing, significantly reducing maintenance difficulty and time costs. For industrial scenarios, this highly maintainable design effectively ensures that the equipment remains in a ready-to-start state at all times, meeting the stringent reliability requirements of fire protection systems.

2. Independent Diesel Power System Ensures Continuous Operation Under Power Outages

During a fire, the power supply system is highly susceptible to interruption due to line damage or load surges, posing a risk of failure for traditional electric fire pumps. Open-type diesel fire pump units use a diesel engine as the power core, operating completely independently of the external power system, and can quickly start working even when the mains power is interrupted. Diesel power features high starting torque, strong adaptability, and safe fuel storage, making it particularly suitable for emergency fire protection scenarios. By rationally configuring the fuel tank capacity, the unit can continuously supply water for a considerable period, meeting the firefighting needs of large industrial facilities or complex fire scenarios, and providing stable and reliable power assurance for the fire protection system. 3. High-Performance Fire Pump Ensures Stable Flow and Sufficient Pressure

As the core operating component of the unit, the performance of the fire pump directly impacts the effectiveness of firefighting. Open-type diesel fire pump units typically utilize high-efficiency centrifugal fire pumps, optimized through hydraulic model design, possessing excellent flow output capabilities and stable head performance. In practical applications, the pump can operate continuously under rated conditions, maintaining minimal pressure fluctuations and uniform flow output, ensuring sufficient water supply to the nozzles or water cannons at the end of the fire protection network. Even under prolonged operation or high load conditions, the pump can still maintain good efficiency, preventing performance degradation from affecting firefighting operations.

4. Skid-Mounted Integrated Base Enhances Overall Stability and Installation Efficiency

Open-type diesel fire pump units generally adopt an integrated skid-mounted steel structure base, integrating the engine, pump body, control system, and piping accessories. This design not only enhances the overall rigidity of the equipment, effectively reducing operating vibrations, but also significantly improves on-site installation efficiency. After the equipment arrives on site, only basic fixing, pipe connection, and simple commissioning are required before it can be put into use, eliminating the need for complex secondary installation work. For emergency projects or industrial construction with tight deadlines, this integrated skid-mounted structure can shorten the construction cycle of the fire protection system and quickly establish reliable fire water supply capabilities.

5. Industrial-Grade Configuration Ensures Reliable Operation in Harsh Environments

In industrial settings such as petrochemical, mining, power generation, and ports, fire protection equipment often faces complex environments with high temperatures, high humidity, dust, and corrosive gases. Open-type diesel fire pump units fully consider these operating conditions during the design phase. Key components are made of wear-resistant and corrosion-resistant materials, and both the engine and pump body have strong environmental adaptability. The open structure facilitates heat dissipation, reducing the risk of performance degradation due to high temperatures. At the same time, through reasonable protection and process treatment, the unit can maintain long-term stable operation in harsh environments, meeting the high standards of reliability required by industrial fire protection systems.

6. Flexible Control Methods Meet Diverse Firefighting Needs

Open-type diesel fire pump units are usually equipped with a complete control system, supporting multiple control modes such as manual start, automatic start, and remote linkage. When the fire protection system receives a pressure drop or fire signal, the unit can automatically start and quickly establish water supply pressure, achieving reliable response under unattended conditions. At the same time, the control system also features operating parameter monitoring, alarm, and protection functions, providing real-time feedback on key data such as engine speed, oil pressure, and water temperature, ensuring the unit remains in a safe operating state. This flexible and reliable control method allows the unit to be easily integrated into various fire control systems.

7. Adaptable to multiple fire protection systems, wide range of application scenarios

The open-type diesel fire pump unit has excellent system compatibility and can be widely used in various fire protection scenarios, including indoor and outdoor fire hydrant systems, automatic sprinkler systems, foam fire extinguishing systems, and fixed water cannon systems. Whether it's a large industrial plant, municipal facilities, or warehousing and logistics centers, or energy stations, this type of unit can be customized to match parameters according to actual needs, providing customized fire water supply solutions. Its flexible application capabilities make it a core power equipment in emergency fire fighting and industrial fire protection systems.

8. Long-term continuous operation capability meets high-intensity fire fighting needs

In major fire accidents, the fire fighting process often lasts for a long time, placing extremely high demands on the continuous operation capability of the fire pump unit. The open-type diesel fire pump unit is designed for long-term stable operation in terms of engine selection, cooling system design, and lubrication system configuration. It can continuously output power at rated conditions without overheating or performance degradation. Reliable continuous operation capability buys valuable time for firefighters, ensuring that fire fighting operations can continue until the fire is completely under control.

9. Simplified operation and maintenance reduces long-term operating costs

From a long-term perspective, fire protection equipment must not only be reliable but also economically efficient. The open-type diesel fire pump unit has a simple structure and clear system, with daily maintenance mainly focused on engine maintenance and pump body inspection. The operation and maintenance process is mature and easy to execute. Commonly used wearing parts are easy to replace, and maintenance costs are controllable, helping to reduce the total cost of ownership over the equipment's lifespan. For industrial users who need to configure fire protection systems for a long time, this type of equipment with low maintenance requirements is more practical.

10. Professional design concept meeting the needs of fire protection engineering

The overall design of the open-type diesel fire pump unit fully follows the usage logic of fire protection engineering. From starting reliability and operating stability to ease of maintenance, all aspects are based on practical needs. It is not a single piece of equipment, but rather a critical power unit in the fire protection system, working in conjunction with pipelines, valves, and control systems to form a complete fire protection system. This engineering-oriented, specialized design gives it irreplaceable value in emergency and industrial fire fighting applications.

In summary, open-type diesel fire pump units, with their independent power source, high reliability, straightforward structure, easy maintenance, and wide applicability, have become essential fire extinguishing power equipment in emergency and industrial fire fighting scenarios. They can operate stably even under extreme conditions such as power outages and can meet the practical needs of complex environments and high-intensity fire fighting tasks. As fire safety standards continue to improve, open-type diesel fire pump units will play a core role in more critical areas, providing continuous and reliable water supply for fire fighting systems.