In modern industrial and municipal safety systems, the response speed and reliability of fire protection systems are crucial. Multi-point jetting fire extinguishing systems have been widely deployed in large industrial plants, petrochemical facilities, storage bases, power substations and other scenarios due to their efficient coverage and ability to adapt to changing fire conditions. The key to supporting the efficient operation of the system lies in the core water pump equipment with sufficient power and stability. To this end, we have launched a horizontal end-suction diesel fire pump set designed for multi-point jetting systems, which takes into account the characteristics of high performance, compact structure, rapid response and durability, and comprehensively improves the output capacity and system safety of fire pump stations.

1. Powerful power system, adapted to multi-point jetting conditions

The horizontal end-suction diesel fire pump is equipped with an industry-leading high-performance diesel engine power system with stable torque output and excellent load response capabilities. It can ensure continuous high-pressure water supply even during multi-point simultaneous jetting and peak water use periods. The diesel engine is precisely matched with the high-efficiency water pump through an elastic coupling to ensure that the overall system output is linearly stable, starts quickly, and is not affected by power outages. This type of system is suitable for the distributed system of spray heads with high requirements for water volume and pressure, and is particularly suitable for heavy-duty spraying environments such as petrochemicals, large-scale logistics warehousing, etc.

2. Horizontal end-suction structure to improve installation flexibility and maintenance efficiency

The classic horizontal end-suction pump body structure is adopted, and the pump shaft and motor shaft are installed coaxially, which occupies a small area and has simple pipe connections, greatly simplifying the installation process. The independent base is welded in one piece, with a stable structure, which effectively reduces the vibration of equipment operation. In terms of maintenance, the horizontal structure provides a larger operating space, which is convenient for replacing key components such as mechanical seals, bearings and maintenance couplings. The structural advantages make this product suitable for the optimization and upgrading of fire pump stations in limited machine room space or renovation projects.

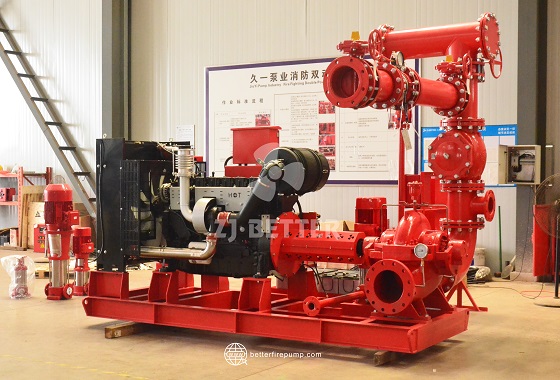

3. Modular complete set design to meet multi-system access

This diesel fire pump system adopts a modular integrated design. The control system, water pump, diesel engine, battery pack and fuel system are all integrated on the integrated base. Comprehensive debugging is completed before leaving the factory. The installation site only needs to connect to the pipeline and power supply to start, which significantly shortens the construction period. At the same time, it supports integration with composite fire protection systems such as foam systems, automatic sprinkler systems, and water cannon systems to meet the increasingly complex multi-system linkage requirements of modern large-scale facilities.

4. High-efficiency hydraulic component design to achieve energy saving and efficiency improvement

The pump adopts advanced CFD fluid simulation design, with excellent hydraulic performance, strong water absorption capacity, stable head, and smooth flow curve. The impeller and pump casing are made of corrosion-resistant cast iron or stainless steel, and a variety of material options are provided according to different application environments to extend the service life while improving operating efficiency. The optimized hydraulic channel design reduces power consumption and achieves energy saving and emission reduction effects, which is especially suitable for fire protection systems with long operating cycles and frequent starts.

5. Intelligent control system, real-time monitoring and remote control

Equipped with a high-performance intelligent control cabinet, integrated PLC controller, touch screen, human-machine interface and fault alarm system, real-time monitoring of the pump group operation status, including diesel engine speed, pressure, temperature, battery voltage and other key parameters. Support local start and stop and remote network control, can be connected to the remote duty system to achieve unattended operation. When the system fails, it has sound and light alarm and log storage functions to facilitate fault tracking and rapid recovery.

6. High reliability diesel power to ensure operation in extreme environments

Select world-renowned brand diesel engines with strong power, low fuel consumption, excellent environmental performance, and adapt to complex working conditions such as high temperature, high humidity, high dust or high altitude. All diesel engines are equipped with dual battery starting system, fuel tank, muffler, water tank and fan cooling system to ensure stable operation around the clock. Even in remote areas or areas with unstable power, high-intensity firefighting tasks can be completed independently, which is particularly suitable for special scenarios such as energy, mining and island projects.

7. Pump body anti-corrosion and whole machine anti-seismic design to extend equipment life

The whole machine is treated with anti-corrosion paint, and the key flow channels inside the water pump can be made of epoxy coating or stainless steel to resist erosion by seawater, acid and alkali liquid or chemical vapor. The base is equipped with rubber shock absorbers and optional spring shock absorbers to effectively suppress vibration transmission and reduce machine room noise. The equipment has high structural strength and excellent fatigue resistance, which meets long-term operation and high-frequency starting occasions, ensuring stable water supply within a life cycle of more than 10 years.

8. Support multi-pump linkage and standby switching mechanism

The system supports multiple pumps running in parallel or switching in turns, automatically starting and stopping according to flow demand, and achieving optimal energy consumption control. It can be combined with an electric main pump to form a dual power system (electric + diesel), and automatically switch to diesel pump operation when the electric pump fails or the power is off. This redundancy mechanism ensures that the water source is not interrupted in critical occasions, and is suitable for scenes such as hospitals, data centers, and airports that have extremely high requirements for water supply continuity.

9. Comprehensive testing and verification, stable at the factory

Each set of equipment completes the full process performance test before leaving the factory, covering parameters such as start-up time, head, flow, system response time, fuel consumption, and alarm function. The testing process is strictly carried out in accordance with the NFPA20 standard to ensure that the delivered products meet the design working conditions. The customer only needs to take over the leveling on site, and it can be put into use quickly, greatly saving the cost of debugging and secondary modification.

10. Wide range of applications, adapted to global standards

The product complies with ISO, NFPA, and CCC standards, and can be customized according to user requirements for CE certification and UL/FM standard design. It is widely used in industrial plants, municipal engineering, underground pipe corridors, commercial complexes, high-rise buildings, refineries, storage and logistics parks, etc., meeting the main pump water supply needs of multi-point jet fire extinguishing systems in various complex scenarios. It is an international high-performance fire-fighting equipment that can truly "go global".

The horizontal end-suction diesel fire pump group is becoming the preferred core power equipment for multi-point jet fire-fighting systems with its strong power, compact structure, intelligent control and wide adaptability. It not only provides the stable high-pressure water source required by the fire-fighting system, but also realizes a reliable, efficient and convenient operation experience through intelligent management and modular design. In the upgrade of modern pump stations and the construction of multi-scenario fire-fighting systems, it is undoubtedly a high-quality solution that takes into account performance, safety and maintenance convenience, and comprehensively improves the response capability and operation efficiency of the overall fire-fighting system.