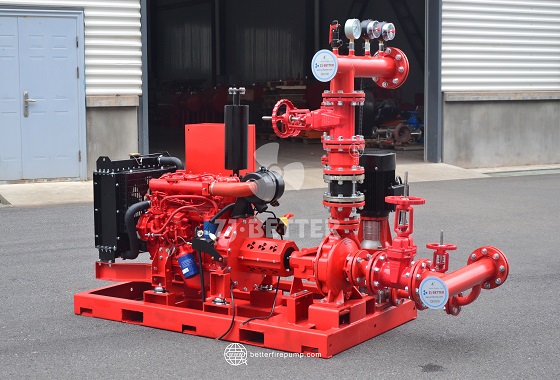

In modern buildings and industrial scenes, higher requirements are placed on the response speed, installation efficiency and space utilization of fire protection systems. Prefabricated diesel fire pump sets, as an integrated solution, perfectly meet this demand. By pre-installing pumps, engines, control systems, bases and other components in the factory, significantly reducing the complexity of on-site construction and achieving efficient deployment is an important development direction of the current fire pump market.

1. Factory pre-installation greatly shortens the construction period

Compared with traditional systems that require multiple links to be assembled on site, pre-installed diesel fire pump sets are pre-assembled by the manufacturer to complete the docking of most components, including bases, electrical control cabinets, water pumps, pipelines and electrical lines. On-site construction only requires simple positioning and interface connection, which greatly reduces the construction period and avoids delays caused by uncontrollable factors such as weather and worker scheduling. For construction units, this "ready-to-use" feature greatly improves efficiency and project controllability.

2. Integrated structure saves floor space

The equipment adopts a highly integrated modular layout, and the pump set, electrical control box and accessories are compactly placed on a unified base, optimizing space utilization. It is especially suitable for basements, equipment rooms or urban projects with tight space. Compared with traditional decentralized layout, this pump group can reduce the installation area by more than 30%, effectively release valuable building space, and bring higher economy.

3. Reduce installation error and debugging difficulty

Since the equipment has been strictly assembled and tested before leaving the factory, the pre-installed pump group basically has no problems such as alignment deviation and circuit connection errors during installation, avoiding the hidden dangers of failure caused by manual splicing. In addition, the overall performance of the pump group has been debugged in the factory, and the user only needs to perform a very small amount of parameter setting and testing on site, which greatly reduces the technical requirements and debugging risks of the installer.

4. Improve system stability and consistency

Since all core components are docked and tested in a controlled environment, the pump group shows higher reliability and consistency during operation. Each pump group meets standardized technical indicators, and batch delivered products can also maintain consistent performance, meeting the strict requirements of large-scale projects for equipment synchronization. This highly standardized solution not only improves operational stability, but also facilitates subsequent operation and maintenance and replacement.

5. Reduce on-site construction and labor costs

The prefabricated design effectively reduces the types of construction work and the number of people required on site, especially in project sites with tight construction schedules or shortage of human resources. The project party does not need to use multiple processes to coordinate, and only needs a few skilled workers to complete the hoisting, wiring, and water and power supply, which greatly saves labor costs and equipment rental costs.

6. Improve emergency response speed

In fire protection systems, the length of response time often determines the safety of personnel and property. The prefabricated diesel engine fire pump unit can be installed and put into operation in a short time due to its "ready-to-use" characteristics. It is especially suitable for emergency projects that need to be delivered quickly, such as petrochemical, warehousing, hospitals and other high-risk places. Once the installation is completed, it can directly enter the linkage test and normal operation stage, winning precious rescue time for the project.

7. Adapt to a variety of working conditions

The prefabricated diesel fire pump unit adopts a modular structure with good flexibility and adaptability. It can be customized according to the different water supply pressure, head, flow and other requirements of the project. Whether in high temperature, high humidity, windy sand or high altitude areas, the normal operation of the equipment can be ensured through preset design and protective measures. The whole machine has the ability to resist earthquake, corrosion, rain and snow, and is suitable for deployment in multiple scenarios such as urban buildings, transportation hubs, tunnel projects, and energy stations.

8. Reduce the frequency and cost of operation and maintenance

The whole machine commissioning and testing before leaving the factory ensures the stability of the long-term operation of the equipment, reduces the failure rate, and reduces the frequency of operation and maintenance. The pre-installed equipment has a compact structure, and standardized components are used in key parts, which is convenient for later maintenance and replacement. At the same time, the unified control system supports one-click self-test and remote diagnosis, helping users to detect and deal with potential faults in time, avoiding fire protection system paralysis caused by equipment downtime, and reducing maintenance costs and labor costs.

9. Easy to transport and deploy globally

The pre-installed diesel engine fire pump group fully considers international transportation standards in size and structure, and is more efficient and free of loose parts when transported as a whole, avoiding the loss of parts. It is particularly suitable for cross-regional and large-scale projects such as overseas projects and the Belt and Road Initiative projects. Customers can quickly install and use the equipment after receiving it, without the need to deploy local parts or professional teams, to achieve rapid deployment and unified standard management worldwide.

10. Meet the needs of modern intelligent control

At present, smart fire protection is developing rapidly. Pre-installed pump sets can easily integrate remote monitoring systems to achieve real-time reporting of equipment operation status, abnormal alarms, data analysis and cloud storage. Through the Internet of Things platform, managers can remotely view the operation data of the pump set, realize intelligent decision-making and remote operation and maintenance, further improve management efficiency and safety level, and help build an efficient, visual and intelligent fire protection system ecosystem.

Pre-installed diesel engine fire pump sets have shown strong application potential in the field of fire protection systems with their excellent integrated design and efficient deployment capabilities. It is not only superior to traditional pump sets in space utilization, construction efficiency and operation stability, but also provides reliable support for modern fire protection management. As a future-oriented product form, pre-installed pump sets will continue to promote the evolution of fire protection systems towards a smarter, more efficient and safer direction.