Product Introduction

ISO series single-stage centrifugal pump is a single-stage single-suction centrifugal pump product developed by China Better Technology Co., Ltd. with reference to international similar products using modern fluid mechanics to meet the international standard ISO9908 secondary energy efficiency standard. This product combines the strengths of similar products at home and abroad and is designed with excellent hydraulic models, therefore, its excellent hydraulic performance and stajctural features ensure that the user can effectively reduce the operating cost of the pump in various applications.

Main Features

• Interchangeable

Meet IS02585, ISO9908 international standards, making it interchangeable with other products that meet the requirements of these standard.

• Structural features of Quality Improvement

The pump body — the pump body is in the form of high-efficiency volute. The flange connection size is in accordance with UL448, FM1319, ANSI/ASME B16.1, ANS1/ASME B16.42, GB/T 17241.6 (cast iron) and GB/T 9113.1 (steel) PN1.6MPa, and can be used with the following standard flanges.: BS 4504: 1989, ISO 7005.1:1992t DIN 2533:1976, ISO 7005.2:1988.

• The rear open cover design — Can replace the rotor components without dismantling the pipeline.

• Replaceable seal ring — The wear of the impeller ring can be achieved only by replacing the sealing ring, so as to restore the best operating condition of the pump and achieve low-cost operation.

• Enhanced pump shaft design …The impeller and the pump shaft are designed with a conical surface to improve the matching precision and bonding strength, which is beneficial for effective locking and convenient maintenance during operation.

• Cantilever ratio is small — The cantilever ratio of the rotor ranges from 0.75 to 1.0f with good rigidity and small deflection. Its rigidity Is much better than that of the same type of single-stage centrifugal pump (the cantilever ratio of IS pump is between 0.97 and 1.48).

• Hydraulic balance design — Further Improve the Stability of Pump Operation, hydraulic balance design and combination of impeller dynamic and static balance.

• Singleend mechanical seal design — suitable for occasions where leakage is not allowed.

• Packing gland design — meets UL/FM standard design and is interchangeable with mechanical seal.

• Reliable bearing structure design — Heavy-duty large-size bearings improve reliability during high-speed and heavy-duty operation. Imported brand Sealed bearings without grease are selected as the standard configuration, bearing inner seal with high quality grease to meet the requirements of maintenance-free and environmental protection during the life of bearings. Oil bath lubrication or grease lubrication bearings are suitable for continuous 24-hour operation and medium temperature greater than 80 C. If grease lubricated bearings or oil lubricated bearings are selected, should inform us when ordering so as to provide more suitable products.

• Rotation direction of the pump — from the driving end, it rotates clockwise.

• Superior technical performance

• Advanced research and development methods — using three-dimensional software and fluid design software for simulation design and CFD software for hydraulic model design and verification, so that the flow characteristics of the pump in the best state, to ensure that the pump has excellent suction performance and operation efficiency.

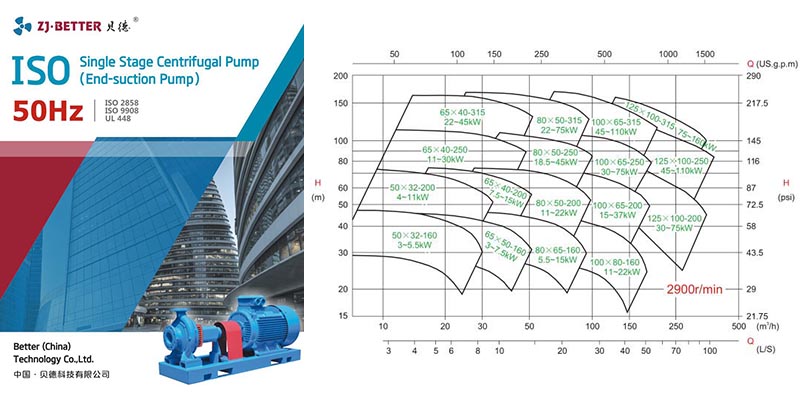

• Wide performance range — beyond IS02858, at the same speed, the flow is 1.6 times, the lift is 1.25 times and 1.8 times (expanding 500mm nominal impeller diameter).