The reason why the fire pump can't pump water and its solution. what is the inspection standard of the fire controller?

2020-04-22

The solution is to check the inlet pipe seal of the self-priming fire pump and repair the leak. For example, the welding place, pipe joint, etc.

Try to run the fire pump about 5 minutes, then stop the machine, close to the pipe, and listen to the sound of air leakage.

2. Self-priming fire pump has been used for a period of time due to corrosion or abrasion, water leakage in the mechanical seal.

Solution: Replace new damaged parts.

3. Due to the large amount of debris in the conveyed liquid, the pipeline or the bottom valve, and even the blockage phenomenon in the pump body.

Solution: Find the specific block point and clean up the debris to solve the problem.

4. Due to the irrational installation of the imported pipeline, for example, the number of elbows is too large, the number of elbows should be controlled as much as 1-2. It is better to use 45-degree elbows when the two elbows are used. The pipe diameter does not match the pump diameter.

5. After the self-priming fire pump pumps the water, it must be filled with water to pump when it is used for the second time, indicating that air has entered the pump body. For example, the outlet pipe of the self-priming fire pump is not installed. Because of the air. After the machine stops, Stop valve will water flow backwards. The air will be sucked into the pump body. Because there is air entering, you need to fill it with water to exhaust it when restart.

Solution: Install a stop valve and ball valve at the outlet. Close the outlet valve before stopping, and then stop.

5. In the actual installation and use of self-priming fire pump, the water suction height exceeds the allowable suction height of the self-priming fire pump. It is recommended to replace a new fire pump with a higher self-priming height or use a submersible pump.

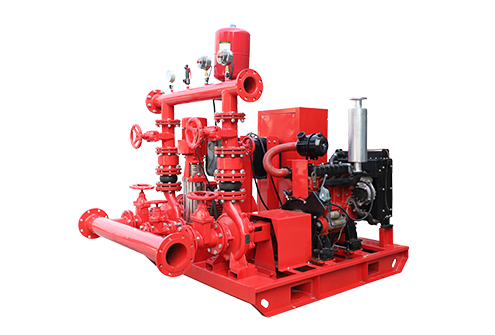

The above are the reasons and solutions for self-priming fire pumps that can't pump water. Buy a self-priming fire pump to find ZJBetter pump, which is safe, reliable and quality guaranteed!

What are the acceptance standards for fire pump control cabinets? Let's take a look at the inspection standards for fire pump control cabinets in the industry.

1) The control cabinet should be straight, and there should be no obvious distortion, warping and corrosion. The surface (the deviation of the verticality of each side is not greater than 1.5 to 3/1000) should be flat, the color of the coating should be uniform, and there should be no reflection of light.

2) The color of the wires, indicators and buttons used in the control cabinet should meet the requirements.

3) The electrical clearance and creepage distance between all live circuits in the control cabinet and between live parts and conductive parts or grounded parts should not be less than 3mm.

4) The insulation resistance between the external live terminals and the cabinet required by the insulated fire-fighting jockey pump in the control cabinet should be greater than 20MΩ, and the insulation resistance between the power terminal and the cabinet should be greater than 50MΩ.

5) Accessible live conductors shall have grounding signs and terminals, and the diameter of the grounding wire shall meet the requirements of the specification.

6) Control functions:

A. The device should have dual power inlets. The dual power supplies should be able to switch automatically and manually. The device can also be equipped with a separate dual power mutual investment cabinet. It should be able to switch automatically and manually. The switching time should not be longer than 2S.

B. The equipment should have three start modes: manual emergency start, automatic start and remote start.

C. When the power frequency operation is adopted, the time for the pump to start and reach the rated water supply parameter should be within 30S.

D. The equipment shall have output terminals showing the working status and fault status of the fire pump, and input terminals for remote linkage and manual control of the fire pump start.

E. When the main fire pump of the equipment is started and operated by power frequency, its stopping of the pump can only be operated manually. When the main fire pump of the equipment is started and operated by frequency conversion, at least one of the working pumps must be manually stopped.

F. When the water level control of the pool is adopted to ensure the fire water consumption, the pump should be able to automatically control the start and stop of the water pump and send an alarm signal in the state of domestic water supply or fire supplementary operation. When entering the firefighting operation state, continuous operation of the fire pump should be guaranteed. When the tank liquid level reaches the limit, the fire pump should be stopped to protect the pump.

G. The equipment should be equipped with automatic and manual switchover of the standby pump when an electrical failure occurs in the fire main pump or the jockey main pump.

H. The equipment should have manual and automatic inspection functions, and its automatic inspection period should be set as required.

I. During the inspection, the pumps start to run at the power frequency one by one, and the running time of each pump is not less than 2MIN, and there should be inspection instructions.

J. The equipment should ensure that during the patrol inspection, it will automatically exit the patrol inspection when it encounters a fire signal and enter the fire operation state.

K. Audible and optical alarms should be provided during the inspection. For equipment with fault memory function, there should be no less than 5 records of fault information, and the display should be clear and easy to understand.

L. The equipment should have self-checking for over-voltage, under-voltage, short-circuit, over-current, motor power failure, etc., fire hydrant pump alarm (alarm should be distinguished by sound) and automatic protection function. The recoverable faults should be eliminated automatically or manually to resume normal operation. M. The buttons, indicators, switches and meters on the control cabinet panel should be set centrally, and at the same time, they should be easy to operate and have function signs.

N. The control cabinet panel should have power and voltage displays, all pump start-stop conditions are displayed, patrol inspection status, fire alarms and fault sound and light alarms are displayed, and various faults should be displayed separately. (Frequency conversion cabinet should have frequency display)

O. It should have the function of automatically adjusting the pressure of fire water supply. (Variable frequency control and reliable voltage stabilization)

P. Equipment for fire pump frequency conversion mode When the frequency converter fails, the fire pump should automatically switch to power frequency mode for fire protection operation in case of fire alarm.

Q. All firfighting contacts are passive contacts.