In various building fire protection systems and industrial fire protection projects, fire pumps, as core water supply equipment, directly affect the success or failure of the overall fire protection system due to their reliability, response speed, and continuous operation capability. Especially in situations such as municipal power outages, sudden fires, or extreme environments, diesel fire pump units with independent power and highly integrated design become crucial equipment for ensuring emergency water supply safety. Integrated control and fuel system diesel fire pump units are integrated fire water supply solutions designed specifically for high reliability, high stability, and rapid response requirements. They can stably output fire water in critical moments, buying valuable time for personnel evacuation and fire control.

1. Diesel-driven design ensures reliable start-up in power outage environments. Integrated control and fuel system diesel fire pump units use a diesel engine as their primary power source. Compared to electric fire pumps, their biggest advantage is that they do not rely on an external power system. When a fire causes a power outage, damage to the power distribution system, or the backup power supply cannot be switched in time, the diesel engine can start independently using its own fuel system, ensuring uninterrupted fire water supply. These units are typically equipped with both electric start and manual emergency start modes, ensuring reliable operation even under extreme conditions. Meanwhile, the low-speed, high-torque output characteristics of the diesel engine ensure smoother start-up of the fire pump under high load, reducing instantaneous impact and ensuring that the outlet water pressure quickly reaches design requirements, creating stable conditions for initial fire suppression.

2. Integrated Fuel System Enhances Continuous Operation Capability

This type of diesel fire pump unit integrates the fuel tank, fuel pipeline, and filtration system into a single design, avoiding operational hazards caused by improper installation, loose interfaces, or insufficient fuel supply in traditional split systems. The independent fuel tank capacity is rationally calculated to meet the requirements of fire codes for continuous operation time, providing sufficient fuel supply during fire response. The fuel system typically employs a multi-stage filtration structure, effectively reducing the impact of fuel impurities on the diesel engine, extending engine life, and improving stability under prolonged high-load operation. This integrated fuel solution is particularly suitable for large buildings and industrial sites with high requirements for continuous water supply time.

3. Intelligent Control System Enables Automated Fire Response

Integrated control is one of the key technical features of this type of diesel fire pump unit. A centralized control cabinet unifies the management of functions such as diesel engine start-up, operation monitoring, pump status feedback, and fault alarms. When the fire protection system detects a drop in pipeline pressure or receives a fire signal, the control system automatically issues a start-up command, enabling the pump unit to operate within a short time. The control system possesses multiple protection functions, including overspeed protection, low oil pressure alarm, and high water temperature alarm, allowing for timely measures to be taken in abnormal situations to ensure equipment and personnel safety. The highly automated control design effectively reduces manual intervention and improves the overall response efficiency of the fire protection system.

4. Optimized Pump Structure Ensures Stable Hydraulic Performance The pump body of the diesel fire pump unit typically adopts a hydraulic model specifically designed for fire protection conditions, ensuring long-term stable operation within the rated flow and rated head range. The internal flow channels of the pump body are meticulously optimized to reduce hydraulic losses and improve overall efficiency, enabling the unit to maintain stable pressure output even under high load operation. Key flow components are mostly made of high-strength, corrosion-resistant materials, meeting the dual requirements of long-term standby and sudden high-intensity operation. A reasonable shaft seal structure and bearing configuration not only reduce operating vibration and noise but also effectively reduce maintenance frequency and improve the long-term reliability of the equipment.

5. Integrated Base Design Enhances System Stability

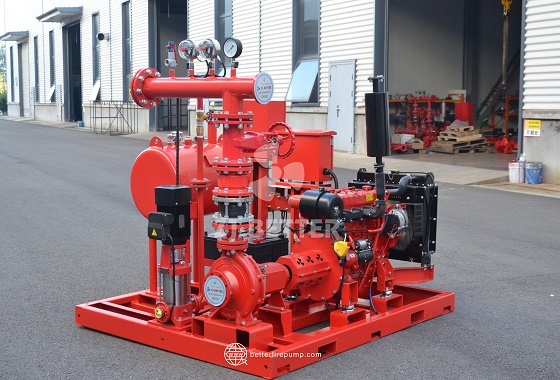

Diesel fire pump units with integrated control and fuel systems typically employ an integral steel base structure, mounting the diesel engine, fire pump, control system, and auxiliary equipment on a single platform. This integrated design significantly improves the overall rigidity and operational stability of the equipment, reducing vibration and displacement issues caused by installation errors. The base is corrosion-resistant, adaptable to various installation environments such as pump rooms, outdoor locations, or semi-open spaces. Furthermore, it facilitates overall transportation and hoisting, reducing on-site construction difficulty, shortening project installation cycles, and providing strong support for project progress.

6. Adaptable to Diverse Firefighting Applications

These diesel fire pump units are widely applicable to various scenarios, including high-rise buildings, commercial complexes, industrial plants, warehousing and logistics centers, and municipal fire protection projects. In these locations, fire protection systems have extremely high requirements for water supply stability and emergency response capabilities. The integrated control and fuel system design allows the unit to be quickly deployed under different environmental conditions, meeting the water supply needs of sprinkler systems, fire hydrant systems, and other fixed fire extinguishing systems. Whether in daily standby mode or during a sudden fire, the unit maintains reliable performance, becoming a core power source in the fire protection system. 7. Compliant with Fire Protection Codes and Engineering Design Requirements

During the design and manufacturing process, the diesel fire pump unit fully considers the relevant fire protection engineering codes and standards. From start-up performance and continuous operating time to control logic, everything is systematically configured. The integrated control system can achieve linkage with the main fire protection control system, meeting the dual requirements of project acceptance and long-term operation. The reasonable structural layout and clear pipeline routing make the equipment easier to pass fire department inspections and acceptance in practical applications, ensuring smooth project delivery.

8. Convenient Maintenance Reduces Long-Term Operating Costs

The integrated diesel fire pump unit is designed with future maintenance needs in mind. Key components are rationally laid out, and maintenance space is ample. The fuel system, control system, and power system are centrally located, making daily inspection and maintenance more intuitive and efficient. Routine maintenance items such as oil changes, filter checks, and battery maintenance can be completed quickly, reducing maintenance time and labor costs. Stable and reliable operating performance reduces equipment failure rates, effectively controlling the overall operating costs of the fire protection system from a long-term perspective.

9. Stable Operation under Complex Conditions

In complex environments with high temperatures, low temperatures, high humidity, or high dust levels, the stability of fire-fighting equipment is paramount. The integrated control and fuel system diesel fire pump unit fully considers environmental adaptability in its material selection and structural design. Through reasonable heat dissipation design and protective measures, it ensures that the diesel engine and control system maintain good performance under complex conditions. This enhanced environmental adaptability design enables the unit to operate reliably in various harsh fire-fighting application scenarios.

10. Improved Safety Redundancy of the Overall Fire Protection System

In modern fire protection engineering, safety redundancy is a crucial concept in system design. The integrated control and fuel system diesel fire pump unit, as an independent power supply device, effectively complements the electric fire pump. When the main power supply system fails, the diesel fire pump can quickly take over, ensuring uninterrupted fire water supply. Through this multi-layered protection mechanism, the overall safety level of the fire protection system is significantly improved, building a more robust defense for building and personnel safety.

Diesel fire pump units with integrated control and fuel systems play an irreplaceable role in modern fire protection systems due to their independent power, intelligent control, integrated structure, and excellent continuous operation capability. These units can not only respond rapidly in emergencies but also maintain stable performance in complex environments and high-intensity operating conditions, providing reliable emergency water supply for various fire protection projects. Through scientific design and highly integrated system configuration, it has become one of the essential basic equipment for ensuring fire safety.