In various fire protection systems, the continuity and stability of water supply are fundamental conditions for effective fire extinguishing, and fire pumps are the core equipment of the entire fire water supply system. Whether in high-rise buildings, industrial plants, or large commercial complexes, the operating status of fire pumps directly affects the response efficiency and actual effectiveness of the fire extinguishing system. As the "power heart" of the system, fire pumps not only need to start quickly in emergencies but also maintain stable output during continuous operation. This article will systematically introduce the core equipment of fire pump systems from multiple aspects, including structural design, performance characteristics, and engineering applications, comprehensively explaining its important role in ensuring the stability of fire water supply.

1. Core Equipment Positioning Determines the Reliability Foundation of the System As the core equipment in the fire water supply system, the performance of the fire pump directly determines the overall reliability of the system. In fire protection systems, pipe networks, valves, and terminal devices all rely on fire pumps to provide a stable water source; once the pump unit malfunctions, the entire system will become ineffective. Therefore, high reliability is the primary goal in the initial design of this type of equipment, emphasizing the strength and stability of key structures. Through reasonable structural layout and rigorous manufacturing processes, fire pumps can smoothly switch between long-term standby and sudden operation, providing a solid and reliable operating foundation for the system.

2. Stable Hydraulic Output Ensures Firefighting Efficiency

The primary task of the core equipment in a fire pump system is to provide a stable hydraulic output. During a fire, the system needs to establish rated water pressure and maintain continuous water supply within a short time, placing high demands on the pump's hydraulic performance. By optimizing impeller design and internal flow channel structure, the fire pump can maintain stable flow rate and head under different operating conditions, avoiding the impact of pressure fluctuations on the firefighting effectiveness of sprinkler or fire hydrant systems. Stable hydraulic output not only improves firefighting efficiency but also enhances the controllability of the entire fire protection system.

3. Structural Strength Meets Long-Term Standby and Emergency Operation

The core equipment of a fire pump system is typically in a standby state for extended periods in practical applications, but once started, it needs to withstand high loads and operate continuously. To adapt to this special operating condition, the equipment's structural design emphasizes strength and durability. The pump body, shaft system, and key connection parts are manufactured using high-strength materials, capable of withstanding the mechanical stresses caused by frequent start-ups and shutdowns and high-pressure operation. This structural design optimized for firefighting conditions effectively reduces the risk of operational failures, ensuring the equipment can be stably put into use at critical moments.

4. Enhanced Operational Stability Improves Overall System Safety

Operational stability is a crucial indicator of fire pump quality. Low vibration and noise during operation of the core equipment in a fire pump system help extend the lifespan of bearings and seals, while minimizing impact on the pump room environment and adjacent equipment. Stable operation not only improves the reliability of the equipment itself but also reduces the probability of system malfunctions, providing strong support for the long-term safe operation of the fire water supply system.

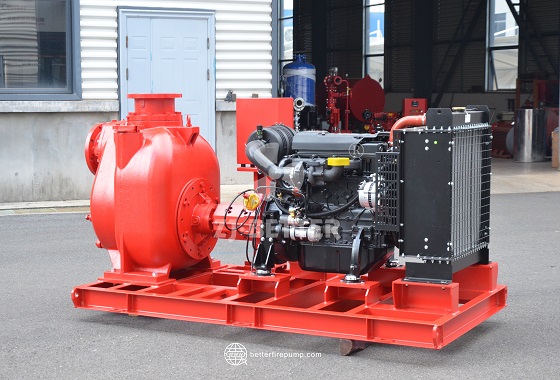

5. Clear Structural Design Facilitates Installation and Management

In engineering projects, equipment installation and subsequent management are equally important. The core equipment of a fire pump system typically employs a clear and rationally laid-out design, making the pump body, inlet/outlet interfaces, and auxiliary components readily apparent. This clear structure not only facilitates on-site installation and system integration but also helps maintenance personnel quickly grasp the equipment status during routine inspections, improving management efficiency and reducing risks caused by improper operation.

6. Excellent System Compatibility Adapts to Multiple Configurations

As a core system component, the fire pump needs to integrate well with various fire protection facilities. This type of equipment can be flexibly applied to various fire-fighting water supply schemes such as fire hydrant systems and automatic sprinkler systems, forming a complete and reliable water supply system through reasonable configuration. Good system compatibility allows the fire pump to adapt to different building types and fire protection design requirements, playing a stable role in diverse engineering projects.

7. Reliable Starting Performance Meets Emergency Needs

In emergency situations during a fire, the ability of the fire pump to start quickly is crucial. The core equipment of the fire pump system has been specially optimized for starting performance, ensuring it remains in good condition even after prolonged standby. Stable starting performance allows the equipment to quickly enter operating condition upon receiving a start signal, buying valuable time for firefighting operations and significantly improving the system's emergency response capability.

8. Convenience of Maintenance Reduces Operating Costs

The long-term operation of a fire pump system relies on standardized maintenance. As core equipment, the fire pump is designed with ease of maintenance in mind, with key components easy to inspect and maintain, and clear and concise daily maintenance procedures. Convenience of maintenance not only reduces the workload of maintenance personnel but also helps to identify potential problems in a timely manner, thereby reducing the risk of downtime due to malfunctions and lowering overall operating costs.

9. Applicable to Diverse Engineering Applications

Fire pump systems, a core component of fire protection systems, are widely used in various engineering projects, including commercial buildings, industrial plants, and warehousing and logistics facilities. Whether for new construction or system upgrades, this equipment can meet fire protection needs of varying scales and complexities through proper selection and configuration. This versatility makes it an indispensable piece of equipment in fire protection engineering design.

10. Ensuring Long-Term Stable Operation of Fire Protection Systems

As a core component of fire water supply systems, fire pumps play a crucial role in the long-term operation of the system. Their stable performance and reliability provide a fundamental guarantee for the effective functioning of fire protection facilities in critical moments. Through continuous and stable water supply, fire pumps provide the necessary conditions for personnel evacuation, fire control, and property protection, forming an important foundation for building highly reliable fire protection systems.

In summary, fire pump systems, as core components of fire water supply systems, bear irreplaceable and critical responsibilities. Their comprehensive performance in structural design, hydraulic performance, operational stability, and system compatibility directly determines the overall reliability level of the fire protection system. Through proper selection and scientific configuration, fire pumps can provide stable and efficient water supply for various engineering projects, and are an important basic equipment to ensure the long-term safe operation of fire protection systems.