In the rapidly evolving landscape of modern urbanization, the complexity of building structures continues to increase, leading to a significant rise in the likelihood and severity of fires. To address different fire scenarios, firefighting equipment must possess high adaptability, reliability, and robust performance. The multi-functional diesel-powered fire pump system is the core equipment developed to meet this demand. It not only features an independent power source, unaffected by power outages, but also leverages powerful flow output and intelligent control technology, making it an ideal fire suppression solution for high-risk areas such as commercial buildings, industrial parks, tunnel infrastructure, large warehouses, and oil and gas chemical facilities.

1. Robust power system ensures independent operation

The diesel engine serves as the core power source and is the most critical component of the multi-functional fire pump system. In the event of a sudden fire causing a power outage, the diesel engine can start quickly without relying on external power supply, ensuring the pump system continues to supply water normally. This system utilizes diesel engines from well-known domestic and international brands such as Cummins, Weichai, and Yuchai, which feature high torque, low fuel consumption, and strong load-bearing capacity. It operates stably under various conditions, including high-altitude, extreme cold, or high-temperature environments, ensuring rapid ignition and stable output to provide continuous water supply support at the fire scene.

2. Efficient pump design for high-flow delivery

The system is equipped with high-performance centrifugal pumps, available in single-stage or multi-stage configurations, optimized for flow rate and head based on specific application requirements. The pump impeller undergoes dynamic balancing to ensure stable operation with minimal vibration, making it suitable for continuous operation tasks. The pump body is made of ductile iron or stainless steel, offering excellent corrosion resistance and suitability for water sources containing impurities or with high acidity/alkalinity, ensuring equipment longevity. Maximum flow rate can reach 300 L/s, with a maximum head of 180 meters, easily meeting the high-pressure, high-flow requirements of large industrial zones, high-rise buildings, and oil storage facilities.

3. Intelligent control module for automatic start/stop functionality

The system is equipped with an advanced PLC intelligent control cabinet supporting multi-language interfaces and featuring automatic start/stop functionality. Through built-in pressure sensors and temperature monitoring devices, the system can monitor the pipeline network status in real time. If the pressure drops below the set value, the system automatically starts the main pump to maintain stable water pressure; once the pressure is restored, the system automatically shuts down to avoid idle running losses. The control system supports communication protocols such as Modbus and RS485, facilitating integration with fire control center hosts to achieve remote monitoring, alarm linkage, and operation permission management, significantly improving operational efficiency and safety standards.

4. Integrated module design for easy installation and maintenance

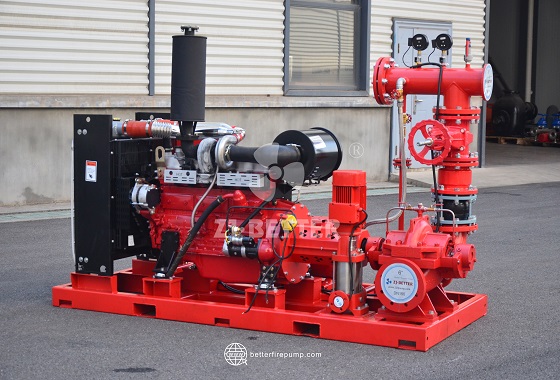

The multi-functional diesel engine fire pump system adopts an integrated base structure, with all components including the diesel engine, water pump, control cabinet, pressure tank, exhaust pipe, etc., fixed on the base platform. The structure is compact and space-saving, making it particularly suitable for pump rooms or container-type units with limited space. The system undergoes comprehensive testing and pressure calibration before leaving the factory. Users only need to connect the piping and cables on-site to quickly put it into operation, significantly reducing the construction period. Additionally, the system is equipped with maintenance access channels and quick-release interfaces, facilitating routine maintenance and emergency repairs, thereby lowering maintenance costs and reducing the risk of failures.

5. Redundant configuration ensures continuous operation

The system can be configured to operate in either a “one active, one standby” or “multiple active, multiple standby” mode according to user requirements. During normal operation, the standby pump remains in standby mode. In the event of a failure or abnormal shutdown of the main pump, the control system automatically switches to the standby pump, ensuring uninterrupted pump station operation and water supply. This redundant design significantly enhances system reliability, making it suitable for locations where water supply interruptions are unacceptable, such as data centers, medical facilities, power plants, and high-risk industrial areas, ensuring the fire protection system remains in a state of readiness at all times.

6. Energy-efficient and environmentally friendly, with low operational costs

Compared to traditional fire pump systems, this diesel engine system has been optimized for energy management. It features an efficient combustion system and low-fuel-consumption injection devices, combined with an engine electronic speed controller that adjusts fuel consumption based on load changes, thereby reducing unnecessary fuel waste. Additionally, the exhaust system is equipped with environmentally friendly mufflers and particulate filters to minimize harmful emissions and noise pollution, meeting environmental standards. Compared to traditional systems on the market, this pump set achieves a 10–20% reduction in overall fuel consumption, significantly lowering operational costs, making it particularly suitable for fire protection applications with high operational frequencies or heavy workloads.

7. Excellent adaptability to meet various scenarios

Whether in conventional buildings or special operation scenarios, this system can operate stably. It is compatible with municipal water supply, self-supplied water sources, and water tank water supply, and is suitable for various environments such as residential buildings, shopping malls, factories, logistics warehouses, airports, subways, tunnels, and chemical industrial parks. Its high-head output capability makes it particularly effective for firefighting water supply in high-rise buildings, and it is also suitable for industrial scenarios requiring long-distance water supply or multi-point spraying, fully meeting the technical requirements of national fire safety standards and international standards.

8. Fault self-diagnosis and alarm system

The system features comprehensive operational status monitoring capabilities, continuously monitoring critical parameters such as diesel engine temperature, pump pressure, lubricating oil pressure, and battery voltage. In the event of abnormal conditions such as overheating, low pressure, oil shortage, stalling, or battery discharge, the system immediately alerts on-site personnel via audio-visual alarms and screen prompts, and automatically stops operation to prevent equipment damage. Some advanced models also support automatic remote push notifications of alarm information to maintenance terminals or mobile apps, enabling smart fire protection maintenance.

9. Safety protection devices ensure system stability

To prevent damage to the pump unit caused by backflow, impact water pressure, and debris blockage in fire environments, the system is equipped with safety protection devices such as check valves, relief valves, and filters. Optional automatic air release valves and bidirectional pressure stabilizing tanks can also be installed to effectively control water hammer effects and system pressure fluctuations. Additionally, the electrical system incorporates multiple safety measures such as short-circuit protection, overload protection, and reverse phase protection. The overall protection rating exceeds IP55, making it suitable for outdoor semi-open or complex environmental conditions.

10. International standard certification and customized services

This system has obtained national CCC certification and can provide customized models in accordance with international standards such as NFPA 20, UL/FM, etc., to meet the fire safety regulations of different countries and projects. Customization services are available, allowing users to customize details such as inlet/outlet direction, pressure range, flange interfaces, and control logic according to project requirements. English operating manuals, overseas remote commissioning support, and installation guidance are provided, with the system widely exported to Southeast Asia, the Middle East, Africa, and South America, receiving high praise from overseas customers.

The multi-functional diesel-powered fire pump system integrates powerful output, intelligent control, high adaptability, and international standard certification, making it a reliable solution for various complex fire scenarios. Whether in infrastructure support, public building fire protection, or emergency systems in high-risk industries, its stable water supply and automatic response capabilities demonstrate outstanding performance. In today's rapidly developing global building intelligence and industrial automation landscape, selecting a safe, efficient, intelligent, and energy-saving fire pump system is a critical step toward enhancing building safety standards and fire emergency response speeds.