1, the skeleton oil seal: short-term cost-effective, but the long-term operation of the comprehensive cost is high; short life (3000h); leakage rate; low speed; wear journal; lubricants easily lost or contaminated. Therefore, long-term continuous operating conditions, should not be used.

2, the labyrinth seal: Advanced than the skeleton oil seal, good performance, no contact; seal structure and equipment line speed and medium viscosity; axial oil leakage situation still exists, can not be used for vertical sealing conditions. Long-term use, oil leakage is still large, the environmental pollution and oil consumption are more difficult to control.

3, the traditional mechanical seal: tight, less leakage; long life; consumption of friction power; shaft or sleeve is not damaged; the vibration of the rotating shaft, yaw and axis of the sealed cavity deflection is not sensitive, Floating good; safe, reliable, long operating cycle; for a wide range. But has certain shortcomings: a high investment, installation time, installation of high precision; and processing of high precision, complex processing, installation of large size. Based on the above characteristics, the use of other sealed equipment for mechanical seal transformation difficult.

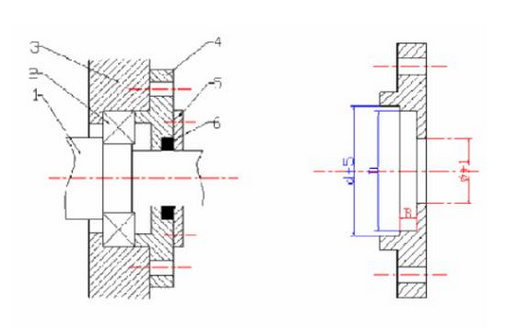

Magnetic seal consists of three parts: the first part of the static sealing surface, it is smooth, thermal stability, ring embedded in a magnetic stainless steel alloy cover; the second part of the dynamic sealing surface, the main material for wear, lubrication Good carbon and graphite, which ring embedded in the magnetic components with the alloy, the dynamic sealing surface with a floating design, the role of the magnetic force in the long-term and the static ring to keep close fit without manual adjustment; The third part is O-ring, the role of the shaft and the moving ring of the sealing surface for sealing, the material is specially treated PTFE.

Leakage caused by two main reasons: First, there is a gap on the sealing surface; Second, there is pressure on both sides of the sealing difference.

Magnetic seal can become an advanced seal structure, the most important because the seal in the design concept inherited the mechanical seal design principles and simplify its structure, improve its function. Magnetic seal has a long service life of the main reasons is to maintain a very thin film between the sealing surface to avoid dry friction between the end, considering the impact of wear and leakage, magnetic seal the best end of the state is the state of lubrication lubrication boundary state.