With the acceleration of industrialization and the continuous advancement of urbanization, the performance requirements for fire protection systems are becoming more and more stringent, especially in critical infrastructures and high-risk operation scenarios, the stability and reliability of fire pumping systems are even more crucial. Diesel-driven fire pump sets, as a kind of core fire-fighting equipment operating independently from the power grid, are widely used in petrochemical, electric power, warehousing, rail transportation and other fields due to their excellent self-sustainability, high efficiency power output, and the ability to adapt to complex environments.

1. Strong power system, guaranteeing continuous water supply

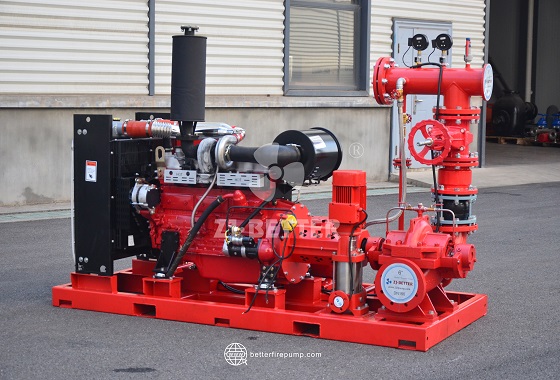

The diesel-driven fire pump set is equipped with a high-performance industrial-grade diesel engine, which ensures that it can still operate independently during power outages or grid interruptions. The engine and pump are connected by a high-efficiency coupling, which optimizes torque transmission, quick startup and timely response. Even in long-time operation or sudden fire, it can still maintain a stable water supply pressure and improve the efficiency of firefighting.

2. Highly reliable design, meet the application requirements of key places

The whole machine adopts modularized structure design, and all key components, such as control system, cooling device and oil system, are selected from international standard configuration to enhance operational safety. Even in the extreme climate or harsh operating environment, the equipment can be maintained in normal operation, providing stable protection for high-risk areas such as oil refineries and hazardous materials warehouses.

3. High-efficiency pump body structure, increase head and flow rate

The pump body adopts advanced hydraulic model design, and the internal impeller channel is optimized to minimize hydraulic loss. According to the site requirements can be configured single-stage or multi-stage pump structure, support high head, large flow rate delivery, to meet the strict requirements of different buildings or facilities on the fire fighting flow and pressure.

4. Intelligent control system, convenient control and real-time monitoring

Equipped with full-automatic electronic control system, it can realize one-key start, automatic switching and fault self-test. The system integrates a number of real-time functions such as pressure monitoring, oil volume alarm, water temperature control, speed display, etc. It supports remote control and data uploading, providing convenient and safe operation and maintenance management.

5. Compact structure, easy to install and arrange

The unit features a compact design with an integrated base for easy lifting and moving, which is suitable for temporary arrangement in machine rooms with limited floor space or in the field, and all the connection interfaces are reserved with uniform specifications, short installation period and simple debugging, which helps to quickly deploy the unit into operation in emergency projects.

6. Durable Materials for Harsh Environment

All metal parts of the equipment are corrosion-resistant, the engine and pump housing are made of cast iron or stainless steel to adapt to high temperature, high humidity, high salt spray and other harsh environments. Pipes and joints are made of industrial-grade sealing materials to ensure long-term operation without leakage and long maintenance cycle.

7. Safe and reliable fuel system with strong endurance

Equipped with large-capacity fuel tank and high-quality fuel lines to ensure uninterrupted operation for a long time. The pipeline is equipped with anti-leakage, anti-vibration and anti-reflux devices, effectively reducing the risk of system failure. The optional dual fuel line design supports automatic switching and standby fuel supply to enhance range protection.

8. Excellent Noise Control Compliant with environmental protection standards.

The combination of low-noise diesel engine and noise elimination device controls the noise of the pumping unit within a reasonable range, especially suitable for urban buildings, tunnels, underground facilities and other places with strict noise control requirements. Equipped with low-noise engines and environmental protection emission standards, the pumps can operate in a green environment without any worry.

9. Easy maintenance, reduce operation and maintenance costs

All maintenance interfaces are reasonably arranged, and routine operations such as oil replacement, coolant replenishment and battery check can be completed quickly. The control system supports fault code display and history query, which is convenient for fault tracing and remote technical support, and greatly reduces the time for on-site manual troubleshooting.

10. Versatile for Multiple Industries, Flexible Configuration

Whether for petrochemical plants, power plants, high-rise buildings, water projects or emergency fire-fighting systems, the pumping unit can be customized according to the needs, including start-up mode, pump type selection, control logic, etc., to ensure that it perfectly matches the needs of the customer's site, and play the maximum performance.

Highly reliable diesel-driven fire pumpsets are ideal for fire emergencies and high-risk scenarios because of their combination of power, construction, intelligent control and durable design. With their combined advantages in efficiency, reliability and ease of maintenance, they provide a reliable firefighting solution for a wide range of industries.