- Centrifugal Pump

-

- IS Single-stage Single-suction Centrifugal PumpS Double Suction Split Case PumpCDL Stainless Steel Multistage Centrifugal PumpIHG Corrosion-resistant Chemical PumpIRG Hot-water PumpISG Single-stage Single-centrifugal PumpISW Single-stage Single-centrifugal PumpISWB Oil Pump (Explosion-proof Motor)ISWH Corrosion-resistant Chemical PumpISWR Hot-water PumpYG Oil Pump (Explosion-proof Motor)

Email: zjbetter@119pump.com

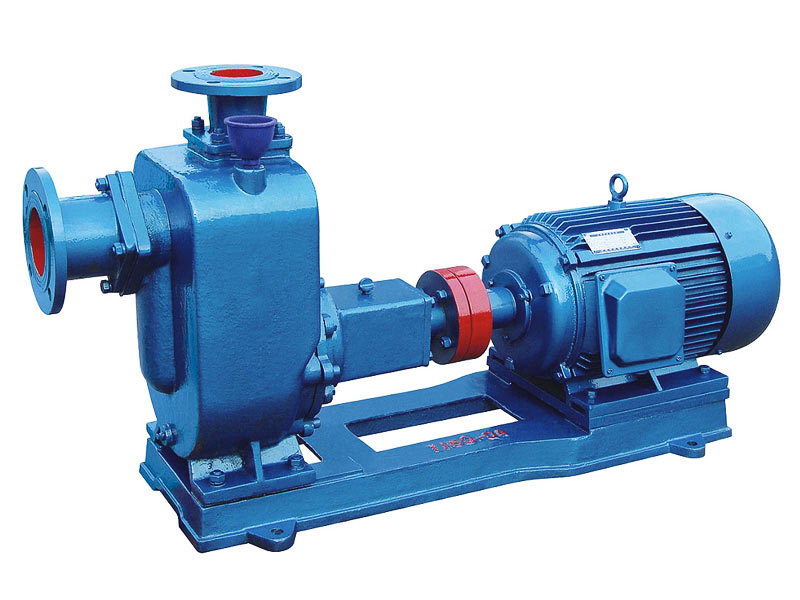

ZX Series Self-suction Pump

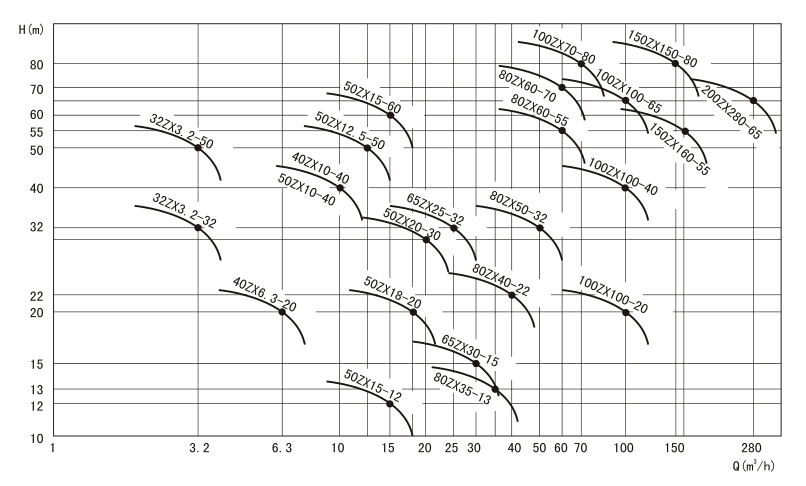

Flow: 2~1000m3/h

Head: 2~80m

Caliber: 25~300mm

Power: 0.75/2P~110/4P kW

Speed: 1450~2900r/min

Working Pressure: 1.0MPa

If you want to get more product information please contact us!

ZX series self-suction pump is an energy saving pump designed with ISO international standard and developed through absorbing and improving the r elated technical data both at home and abroad and belongs to the self-suction centrifugal pump and uses the mechanical seal of a ceramic ring so as to resist any sandy liquid to go into the sealing face, preventing it from getting scratched. This pump holds the advantages of a compact structure, easy operation, stable movement, easy maintenance, high efficiency, long duration and strong self-suction capacity and, as no foot valve is needed to be mounted on the pipeline and only a certain amount of leading liquid is required to be filled into the pump before work, improves the work condition while simplifying the pipeline system.

Model explanation

ZX L P 40 – 32 – 160

ZX — Self-priming centrifugal pump

L — Direct- connected

P — * P Stainless steel

* B Explosion-proof

40 — Inlet diameter (16kg flange)

32 — Outlet diameter (6kg flange)

160 — Impeller diameter

1.Suitable for city environmental protection , construction, fire fighting, chemical industry, pharmacy, dyes, dyeing, brewing, electric power, electric plating, paper-making, industrial and mineral rinse, equipment cooling and so on.

2. This pump, when mounted with a shaking arm shower, c an have the water burst into air and then scattered in a thin drop for spraying, useful to a farm, nursery, orchard and tee plantation.

3. Suitable for pure water, sea water, the chemical media of an acid and alkaline degree and the pulpy material of a general pasty state (medium viscosity<=100cP, solid content below 30%).

4. This pump can work together with a pressure filter of any model and specification and is the most ideal matching pump to send pulpy materials to the s aid filter f or pressure filtering.

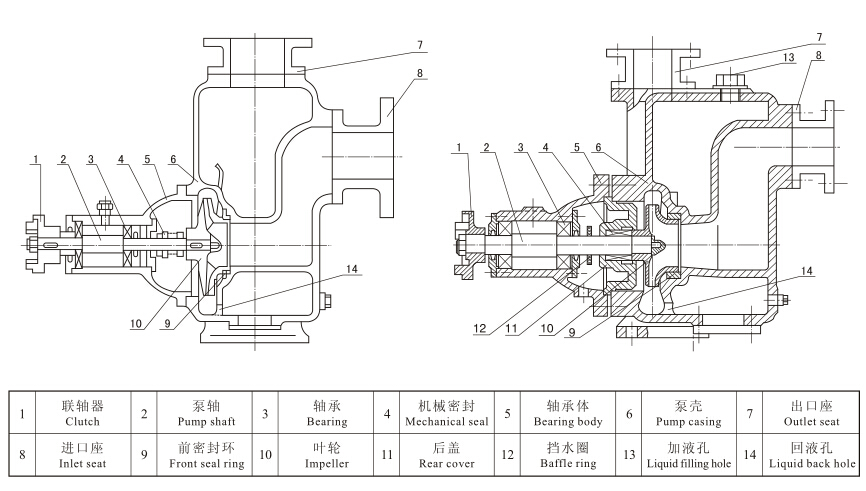

2. Using Instruction

1. Check if the stored liquid inside of the pump casing is above the upper edge of the impeller and, if not, p rime liquid directly from the filling port on the casing. Do not start the pump in case of an insufficient stored liquid, or the pump would not work normally and the mechanical seal would be easily damaged.

2. Check if the moving parts of the pump are jammed or collided; if the foot on the pump bottom and the nuts on the joints are loose; check the concentricity or the parallelism between the shafts of both pump and motor; c heck if there is air-leaking with the inlet pipeline and settle it if any; open the valve on the suck-in pipeline and slightly open (not fully) the outlet control valve.

3. Pay attention to the pump shaft to see if it moves in the correct direction when to start the self-suction pump, and if there is abnormal sounds and vibration when it moves

2. Specifications

| Model | Flow(m3/h) | Head(mpa) | Power(kw) | Speed(rpm) | Caliber (mm) |

| ZX20-20-125 | 1.2 | 20 | 0.55 | 2900 | 20/20 |

| ZX25-20-160A | 2.8 | 28 | 1.1 | 2900 | 25/20 |

| ZX32-25-200 | 3.6 | 50 | 4 | 2900 | 32/25 |

| ZX40-32-250 | 5 | 80 | 7.5 | 2900 | 40/32 |

| 1.2 | 20 | 1.1 | 1450 | ||

| ZX40-32-250B | 4.4 | 60 | 4 | 2900 | 40/32 |

| 1 | 15 | 0.55 | 1450 | ||

| ZX50-40-125 | 10 | 20 | 1.5 | 2900 | 50/40 |

| ZX50-40-250 | 10 | 80 | 11 | 2900 | 50/40 |

| 5 | 20 | 1.5 | 1450 | ||

| ZX65-50-200 | 20 | 50 | 7.5 | 2900 | 65/50 |

| 10 | 12 | 1.1 | 1450 | ||

| ZX65-50-250A | 18 | 70 | 11 | 2900 | 65/50 |

| 9 | 17 | 1.5 | 1450 | ||

| ZX80-65-160 | 40 | 32 | 7.5 | 2900 | 80/65 |

| ZX80-65-250B | 34.6 | 60 | 15 | 2900 | 80/65 |

| 8 | 15 | 1.5 | 1450 | ||

| ZX100-80-125A | 71.2 | 16 | 7.5 | 2900 | 100/80 |

| ZX100-80-250 | 80 | 80 | 37 | 2900 | 100/80 |

| 40 | 20 | 5.5 | 1450 | ||

| ZX125-100-125 | 128 | 20 | 15 | 2900 | 125/100 |

| ZX125-100-315 | 128 | 125 | 90 | 2900 | 125/100 |

| 60 | 30 | 15 | 1450 | ||

| ZX150-100-250 | 160 | 80 | 75 | 2900 | 150/100 |

| 75 | 20 | 15 | 1450 | ||

| ZX150-100-350 | 128 | 150 | 110 | 2900 | 150/100 |

| 60 | 35 | 22 | 1450 | ||

| ZX200-150-200 | 180 | 12.5 | 15 | 1450 | 200/150 |

| ZX200-150-250 | 180 | 20 | 18.5 | 1450 | 200/150 |

| ZX250-200-250 | 495 | 20 | 45 | 1450 | 250/200 |

| ZX250-200-400B | 428.4 | 37.5 | 75 | 1450 | 250/200 |

| ZX300-250-315B | 522 | 24 | 55 | 1450 | 300/250 |

| ZX350-300-250 | 720 | 20 | 75 | 1450 | 350/300 |

| ZX350-300-315A | 648 | 28 | 90 | 1450 | 350/300 |

| ZX400-350-625 | 972 | 32 | 132 | 970 | 400/350 |

| ZX500-400-625 | 1080 | 32 | 160 | 970 | 500/400 |

| MORE SPECIFICATIONS PLEASE CONTACT US. | |||||

Related products

InquiryPlease Feel free to give your inquiry in the form below. We will reply you in 24 hours.