- Centrifugal Pump

-

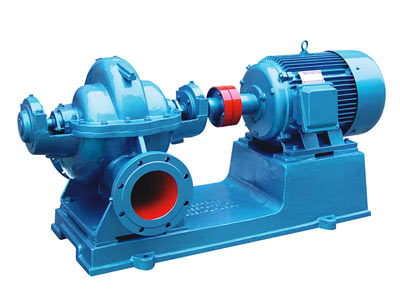

- IS Single-stage Single-suction Centrifugal PumpS Double Suction Split Case PumpCDL Stainless Steel Multistage Centrifugal PumpIHG Corrosion-resistant Chemical PumpIRG Hot-water PumpISG Single-stage Single-centrifugal PumpISW Single-stage Single-centrifugal PumpISWB Oil Pump (Explosion-proof Motor)ISWH Corrosion-resistant Chemical PumpISWR Hot-water PumpYG Oil Pump (Explosion-proof Motor)

Email: zjbetter@119pump.com

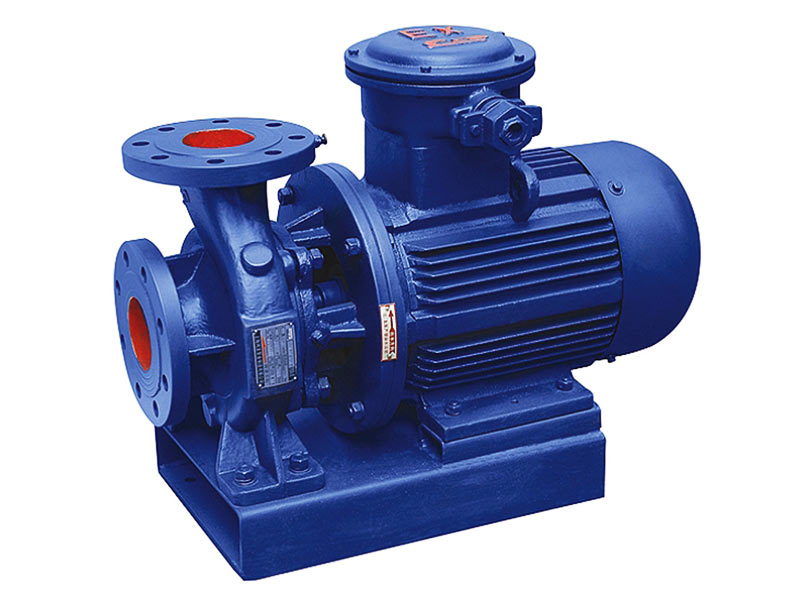

ISWB Oil Pump (Explosion-proof Motor)

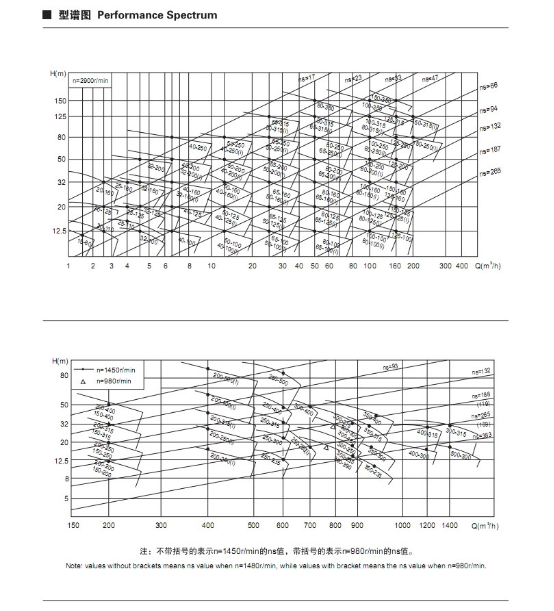

Flow: 1~1800m3/h

Head: 2~150m

Caliber: 15~500mm

Power: 0.18~160/6P kW

Speed: 960~2900r/min

Working Pressure: 1.6MPa

If you want to get more product information please contact us!

ISG series vertical single-stage single-suction centrifugal pump is a new generation of energy saving, environment friendly vertical centrifugal pump researched and developed by our company, which absorbs advanced technology of similar products abroad and adopts domestic general performance parameters of centrifugal pumps. In addition, according to different operation temperatures and mediums, we developed the hot-water pump (IRG), corrosion-resistant chemical pump (IHG) and oil pump (YG). This pump enjoys excellent performance, good reliability, long operation life, reasonable construction and nice appearance, which is outstanding in the industry.

Model Meaning

ISG 50 - 160 (I) A (B)

ISG — *ISG, ISW single-stage single-centrifugal pump

*IHG, ISWH corrosion-resistant chemical pump

*IRG, ISWR hot-water pump

*YG, ISWB Oil pump (explosion-proof motor)

50 — nominal diameter of pump inlet and outlet (mm)

160 — impeller nominal outside diameter (mm)

I — Flow classification

A — impeller through first-cutting

B — impeller through second-cutting

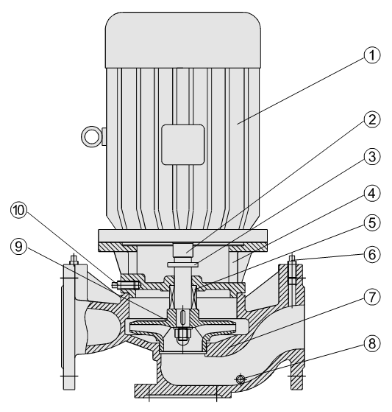

1. Y/Y2 Series Motor: the driving part of pump, with a close- coupled type.

2. Pump Shaft: coaxial with motor and high concentricity to enable pump operating without noise and vibration.

3. Water Deflector: to avoid water entering motor due to leakage at seal.

4. Pump Cover: elaborately designed of sharing the same end cover with motor, shortened axial dimensions and simple structure.

5. Mechanical Seal: made of stainless steel, tungsten carbide, fluorine rubber and etc, for outstanding sealing, durable service life and leak-tightness.

6. Pressure Plug: to mount pressure gauge to monitor the normal operation of pump.

7. Pump Body: to lower the velocity of flow, making velocity energy into pressure energy

8. Drain Plug: fully let out the liquid inside in case that pump needs servicing or will be left unused for a long time.

9. Air Release Valve: to release the air inside to ensure the normal start of pump.

10. Impeller: to play a leading role with its vane forcing liquid rotated and splashed around driven by centrifugal force.

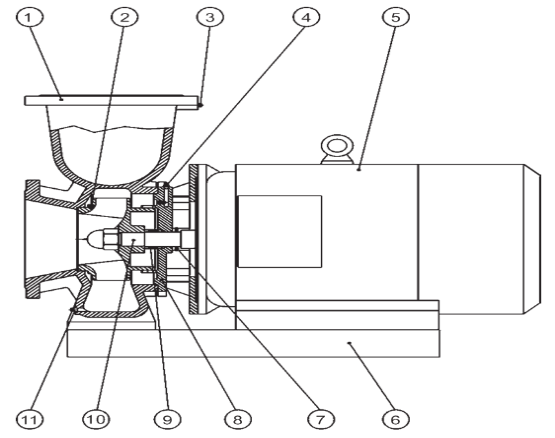

2. Horizontal

1. Pump Body: to lower the velocity of flow, making velocity energy into pressure energy.

2. Impeller: to play a leading role with its vane forcing liquid rotated and splashed around driven by centrifugal force.

3. Pressure Plug: to mount pressure gauge to monitor the normal operation of pump.

4. Air Release Valve: to release the air inside to ensure the normal start of pump.

5. Y/Y2 Series Motor: the driving part of pump, with a close coupled type.

6. Base: pump’s foundation, to ensure the stable of installation.

7. Water Deflector: to avoid water entering motor due to leakage at seal.

8. Pump Cover: elaborately designed of sharing the same end cover with motor, shortened axial dimensions and simple structure.

9. Mechanical Seal: made of stainless steel, tungsten carbide, fluorine rubber and etc, for outstanding sealing, durable service life and leak-tightness.

10. Pump Shaft: coaxial with motor and high concentricity to enable pump operating without noise and vibration.

11. Drain Plug: fully let out the liquid inside in case that pump needs servicing or will be left unused for a long time.

Deliver fresh water or the liquid which its chemical character is similar to fresh water. Industry and city water supply and drainage.

2. Using Instruction

Before start:

1. Turning the clutch by hand, there should be no jammed phenomenon at the turner position.

2. Opening the inlet valve and the vent valve, letting the water fill into the pump's chamber, then closing the vent valve.

3. Clicking the switch of motor, and confirming whether the turning is right or not.

Running:

1. Fully opening the inlet valves, and closing the valves of the outlet pipe.

2. Connecting the power, Opening the valves of the outlet pipe and adjusting the needed working point when the turning velocity is normal.

3. Watching whether there exist abnormities or not, if yes, should the pump be stopped and inspected before re-running.

Stop:

1. After turning off the outlet valves one by one, shutting off the power.

2. Shutting off the inlet valves.

3. If the ambient temperature is below 0, some warm keeping measures should be adopted.

2. Specifications

| Model | Flow(m3/h) | Head(mpa) | Power(kw) | Speed (rpm) | Caliber (mm) |

| 25-125 | 4 | 20 | 0.75 | 2900 | 25 |

| 25-160 | 4 | 32 | 1.5 | 2900 | 25 |

| 32-100 | 4.5 | 12.5 | 0.55 | 2900 | 32 |

| 32-200 | 4.5 | 50 | 3 | 2900 | 32 |

| 40-160A | 5.9 | 28 | 1.5 | 2900 | 40 |

| 40-200 | 6.3 | 50 | 4 | 2900 | 40 |

| 40-250 | 6.3 | 80 | 7.5 | 2900 | 40 |

| 40-250(I) | 12.5 | 80 | 11 | 2900 | 40 |

| 50-125A | 11 | 16 | 1.1 | 2900 | 50 |

| 50-200 | 12.5 | 50 | 5.5 | 2900 | 50 |

| 50-250 | 12.5 | 80 | 11 | 2900 | 50 |

| 50-315(I)B | 22.5 | 101 | 18.5 | 2900 | 50 |

| 65-125A | 22.3 | 16 | 2.2 | 2900 | 65 |

| 65-200B | 21.8 | 38 | 4 | 2900 | 65 |

| 65-250 | 25 | 80 | 15 | 2900 | 65 |

| 65-315(I) | 50 | 125 | 37 | 2900 | 65 |

| 80-160 | 50 | 32 | 7.5 | 2900 | 80 |

| 80-250 | 50 | 80 | 22 | 2900 | 80 |

| 80-350 | 50 | 150 | 55 | 2900 | 80 |

| 80-315(I) | 100 | 125 | 75 | 2900 | 80 |

| 100-125A | 80 | 16 | 7.5 | 2900 | 100 |

| 100-200A | 93.5 | 44 | 18.5 | 2900 | 100 |

| 100-250 | 100 | 80 | 37 | 2900 | 100 |

| 100-350 | 100 | 150 | 90 | 2900 | 100 |

| 125-160 | 160 | 32 | 22 | 2900 | 125 |

| 125-200 | 160 | 50 | 37 | 2900 | 125 |

| 125-250 | 160 | 90 | 55 | 2900 | 125 |

| 125-315A | 150 | 110 | 75 | 2900 | 125 |

| 150-160B | 140 | 24 | 15 | 2900 | 150 |

| 150-250 | 200 | 80 | 75 | 2900 | 150 |

| 150-315A | 187 | 110 | 90 | 2900 | 150 |

| 150-350 | 160 | 150 | 110 | 2900 | 150 |

| more specifications pls feel free to contact us. | |||||

Related products

-

- IS Single-stage Single-suction Centrifugal Pump

-

- S Double Suction Split Case Pump

-

- CDL Stainless Steel Multistage Centrifugal Pump

-

- IHG Corrosion-resistant Chemical Pump

-

- IRG Hot-water Pump

-

- ISG Single-stage Single-centrifugal Pump

-

- ISW Single-stage Single-centrifugal Pump

-

- ISWH Corrosion-resistant Chemical Pump

-

- ISWR Hot-water Pump

-

- YG Oil Pump (Explosion-proof Motor)

InquiryPlease Feel free to give your inquiry in the form below. We will reply you in 24 hours.