- Centrifugal Pump

-

- IS Single-stage Single-suction Centrifugal PumpS Double Suction Split Case PumpCDL Stainless Steel Multistage Centrifugal PumpIHG Corrosion-resistant Chemical PumpIRG Hot-water PumpISG Single-stage Single-centrifugal PumpISW Single-stage Single-centrifugal PumpISWB Oil Pump (Explosion-proof Motor)ISWH Corrosion-resistant Chemical PumpISWR Hot-water PumpYG Oil Pump (Explosion-proof Motor)

Email: zjbetter@119pump.com

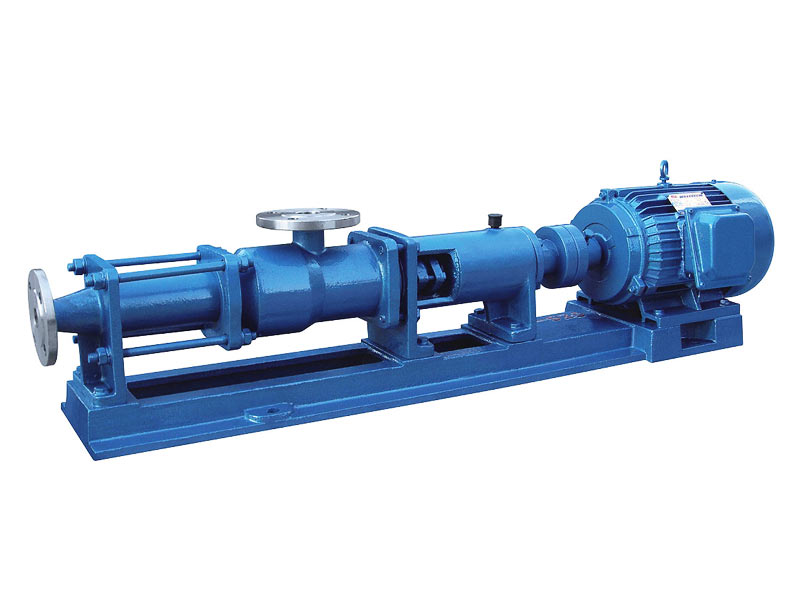

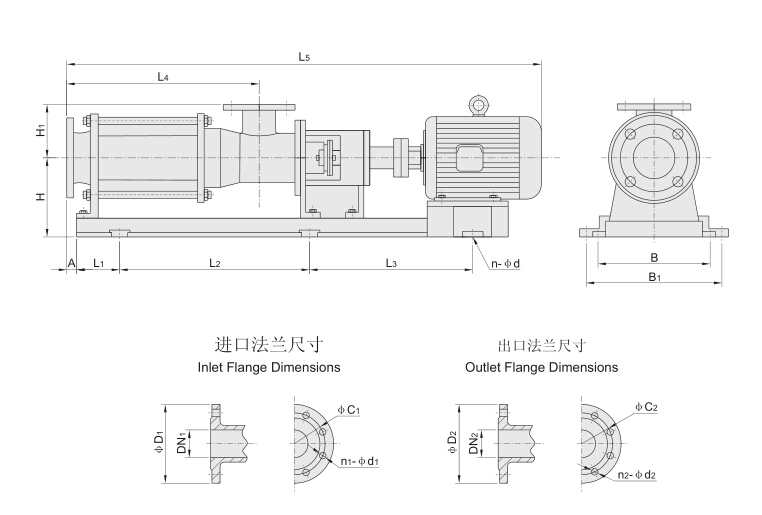

G Single Screw Pumps

Flow: 0.8~150m3/h

Caliber: 25~250mm

Pressure: 0.6~1.2MPa

Power: 0.75~37kW

Speed: 400~960r/min

Working Pressure: 1.6MPa

If you want to get more product information please contact us!

G Single Screw Pumps is an enclosed screw pump with inner gearing, a kind of rotor positive-displacement pump. As this kind of pump is characterized by being adaptable for the medium, stable flow, good suction performance and small pressure pulsation, it can transfer very viscous media or those containing hard suspended or solid grains or fiber apart from various flowing media. Besides, it boasts good adjusting performance, wide range and high efficiency. Therefore, it is widely applied in various industries like environmental protection, shipping, petroleum, pharmacy, household chemical, food, brewage, construction, mining, chemistry, printing, paper making, power plants and boilers.

It can be used in the pump oil, waste oil, pulp, mud, chemicals and chemical grout, glue, paint, syrup, jam, condensed water and other cosmetics as well as the transmission medium.

2. Using Instruction

1. Pump piping should not allow ourselves to bear the weight of import and export control should have its own bracket bearing, so as to avoid deformation due to stress damage the pump.

2. If the new pump haven't use for a long time, should inject an amount of cleanser essence before using, and then trip the pump to reverse direction by tong, it can start when pump body is fully lubricated.

3. Pre-boot bearing box should be added enough oil (butter).

4. Opened full inlet of valves, opened full outlet valve, inching pump, then adjusting the motor swerve according to pump swerve.

5. Opened full inlet of valves, opened full outlet valve, pump started. Motor reaches the normal speed until after the off slowly small export valves, regulating valves to enable the export nameplate pressure gauge reading head in line with the pump.

6. In the operation of the process, found to have abnormal sounds or other failure, should immediately stop checks, when troubleshooting before they can continue to use.

7. Transport of high viscosity or containing particles and the corrosive medium, the application of water or solvent washing to prevent clogging, so next time you start difficulties

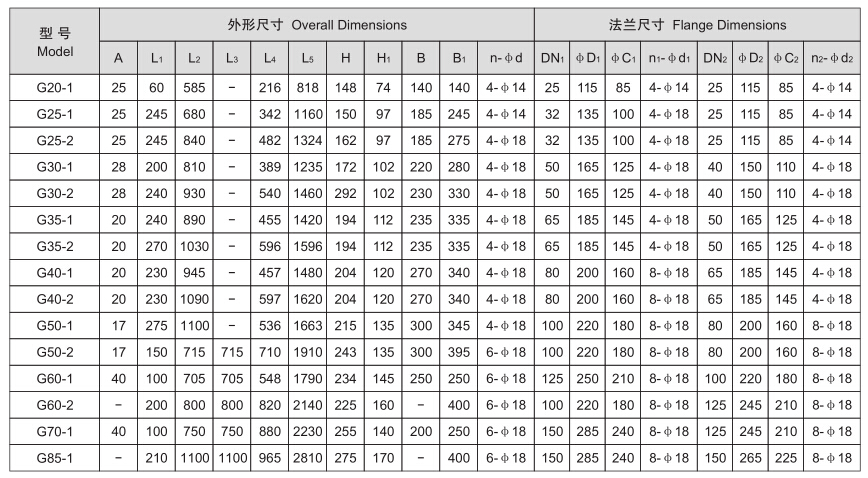

2. Specifications

| Model | Flow(m3/h) | Head(mpa) | Power(kw) | Speed(rpm) | Caliber (mm) |

| G20-1 | 0.8 | 60 | 0.75 | 960 | 25/25 |

| G20-2 | 0.8 | 120 | 1.5 | 960 | 25/25 |

| G25-1 | 2 | 60 | 1.5 | 960 | 32/25 |

| G25-2 | 2 | 120 | 2.2 | 960 | 32/25 |

| G30-1 | 5 | 60 | 2.2 | 960 | 50/40 |

| G30-2 | 5 | 120 | 3 | 960 | 50/40 |

| G35-1 | 8 | 60 | 3 | 960 | 65/50 |

| G35-2 | 8 | 120 | 4 | 960 | 65/50 |

| G40-1 | 12 | 60 | 4 | 960 | 80/65 |

| G40-2 | 12 | 120 | 5.5 | 960 | 80/65 |

| G50-1 | 14 | 60 | 5.5 | 960 | 100/80 |

| G50-2 | 14 | 120 | 7.5 | 960 | 100/80 |

| G60-1 | 22 | 60 | 11 | 960 | 125/100 |

| G60-2 | 22 | 120 | 15 | 960 | 125/100 |

| G70-1 | 38 | 60 | 11 | 720 | 150/125 |

| G70-2 | 38 | 120 | 18.5 | 720 | 150/125 |

| G85-1 | 56 | 60 | 15 | 960 | 150/125 |

| G85-2 | 56 | 120 | 15 | 960 | 150/125 |

| MORE SPECIFICATIONS PLEASE CONTACT US. | |||||

Related products

InquiryPlease Feel free to give your inquiry in the form below. We will reply you in 24 hours.